DRI GARD SW 100 chemical resistant epoxy coating Dritech Protective Coatings

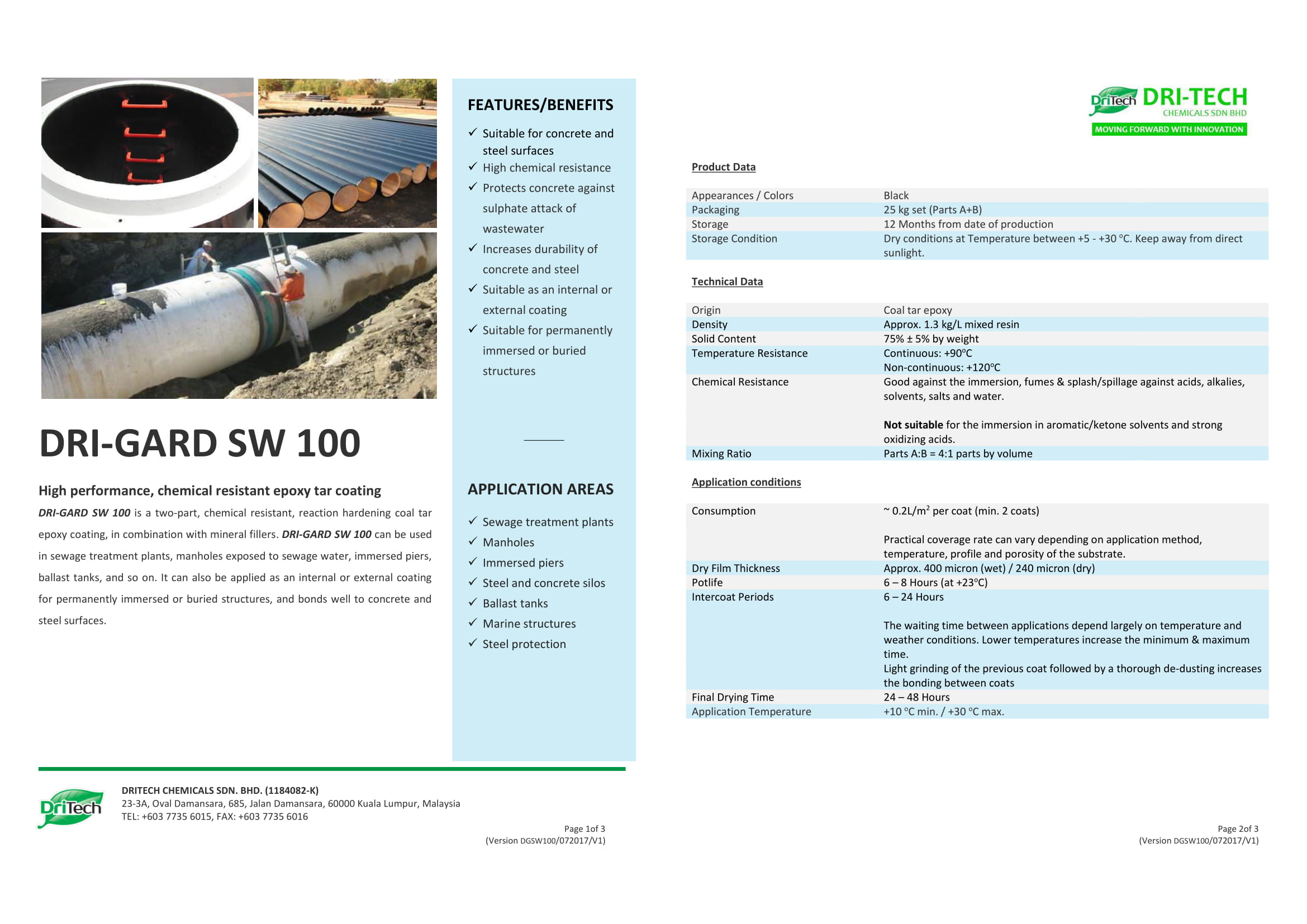

DRI GARD SW 100 chemical resistant epoxy tar coating is a two-part, chemical resistant, reaction hardening coal tar epoxy coating, in combination with mineral fillers. DRI-GARD SW 100 can be used in sewage treatment plants, manholes exposed to sewage water, immersed piers, ballast tanks, and so on. It can also be applied as an internal or external coating for permanently immersed or buried structures, and bonds well to concrete and steel surfaces.

DRI GARD SW 100 chemical resistant epoxy tar coating most suitable to be used in Sewage treatment plants, Manholes, Immersed piers, Steel and concrete silos, Ballast tanks, Marine structures, Steel protection

Protective Coatings

Coal tar epoxy

NA

| Feature | Performance |

|---|---|

| Versatile | Suitable for concrete and steel surfaces. Suitable as an internal or external coating. Suitable for permanently immersed or buried structures. |

| Chemical resistant | Protects concrete against sulphate attack of wastewater |

| Durable | Increases durability of concrete and steel |

| Specification | Properties |

|---|---|

| Density | Approx. 1.3 kg/L mixed resin |

| Solid Content | 75% ± 5% by weight |

| Temperature Resistance | Continuous: +90oC Non-continuous: +120oC |

| Chemical Resistance | Good against the immersion, fumes & splash/spillage against acids, alkalies, solvents, salts and water. Not suitable for the immersion in aromatic/ketone solvents and strong oxidizing acids. |

| Mixing Ratio | Parts A:B = 4:1 parts by volume |

| Consumption | ~ 0.2L/m2 per coat (min. 2 coats) |

| Dry Film Thickness | Approx. 400 micron (wet) / 240 micron (dry) |

| Potlife | 6 – 8 Hours (at +23oC) |

| Intercoat Periods | 6 – 24 Hours |

| Final Drying Time | 24 – 48 Hours |

| Application Temperature | +10 oC min. / +30 oC max. |

NA

NA

NA

| Company | Installation | Minimum Order | Cover area |

|---|---|---|---|

| (Chemical Supplier and Manufacturer) | Yes | 0 | Cyberjaya, Johor, Kedah, Kelantan, Kuala Lumpur, Malacca, Negeri Sembilan, Pahang, Penang, Perak, Perlis, Putrajaya, Selangor, Terengganu |

| No Result found. | |||

No Photo & Brochure available