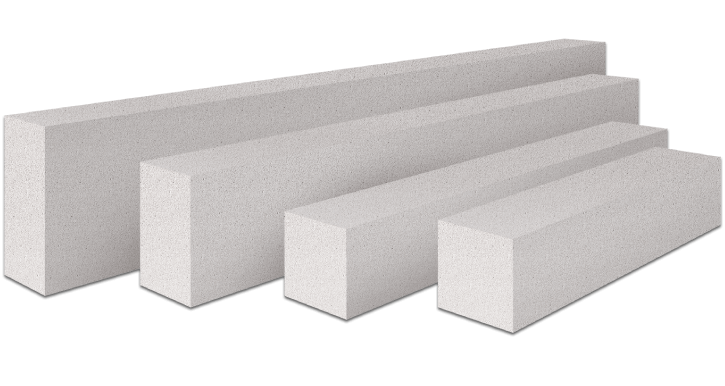

Lintel Starken

Refer to lintel table for standard sizes. Please contact Starken AAC Technical Department on information related to allowable working load.

Lintels are also used as spreaders under the end supports of reinforced concrete beams to distribute high bearing stresses into the supporting AAC wall.

Lintels are also used as spreaders under the end supports of reinforced concrete beams to distribute high bearing stresses into the supporting AAC wall.

Starken AAC Lintels are reinforced elements similar to panels. They are used as support over windows, doorways and other openings.

Autoclaved Aerated Concrete (AAC) Blocks

Sand, Concrete, Autoclaved Aerated Concrete (AAC) Blocks

NA

| Feature | Performance |

|---|---|

| Lightweight | Starken AAC density is about one-fifth of that of normal concrete blocks, making it easily handled. |

| Heat resistant | Starken AAC's excellent thermal insulation properties result in improved comfort level and saves heating and cooling costs. Building uses approximately 30% less energy for cooling and heating the interior air space. Heat insulation 6 times superior than clay brick |

| Impact resistant | Wall erected using 100 mm thick AAC products is classified as “Severe Duty” grade and able to withstand impact loads potentially resulting from rough usage. |

| Water resistant | Starken AAC contains millions of closed microscopic cells which strongly resist moisture from passing through. |

| Sound insulation | Scientifically proven to provide better insulation to sound transmitted by air compared with other solid building materials. |

| Fire resistant | More superior than traditional masonry for products with fire resistant up to 4 hours for a nominal block thickness of 100 mm. |

| Durability | History of usage dated more than 50 years protecting building envelopes and remain durable even under extreme weather conditions. |

| Cost saving | Speed and ease of installation result in cost savings compared to traditional masonry construction. Save up to 25% of Foundation Cost. |

| Environmental friendly | Starken AAC to help reduce at least 30% of environmental waste, decrease 50% of greenhouse radiation and over 60% integrated energy on the surface of brick. |

| Balanced thickness | Blocks and panels are manufactured under factory environment using state-of-the art modern machineries resulting in products with tighter dimensional tolerances. |

| Easy installation | Starken AAC can be easily sawn, cut, carved, nailed or drilled using ordinary hand tools. |

| Time saving | Wall Installation, internal and external wall finishing are quicker than conventional bricks. Since required only skim coat and render. |

| Specification | Properties |

|---|---|

| Dimension (L x W x H) | 1200mm x 900mm x 200mm 1600mm x 1200mm x 200mm 1900mm x 1600mm x 200mm 1800mm x 2200mm x 300mm 2700mm x 2100mm x 300mm |

| Compressive Strength | 3.5MPa |

| Density | Nominal Dry Density: 550 kg/m3 Working Density: 780 - 820 kg/m3 |

| Thickness | 100, 125, 150, 175, 200mm |

NA

NA

NA

| Company | Installation | Minimum Order | Cover area |

|---|---|---|---|

| No Result found. | |||

No Photo & Brochure available