Single Stage Steam Turbine Multico Clean and Renewable Energy

Siemens DR SST 500 700 is a Dresser-Rand Single Stage Steam Turbine that compliant with API 611 and API 612. This rugged steam turbine is reliable mechanical drive and economical for lube oil pumps, process pumps, feedwater pumps, fans, compressors, generators as specified by the petrochemical, food processing, refining, steel, and other industries.

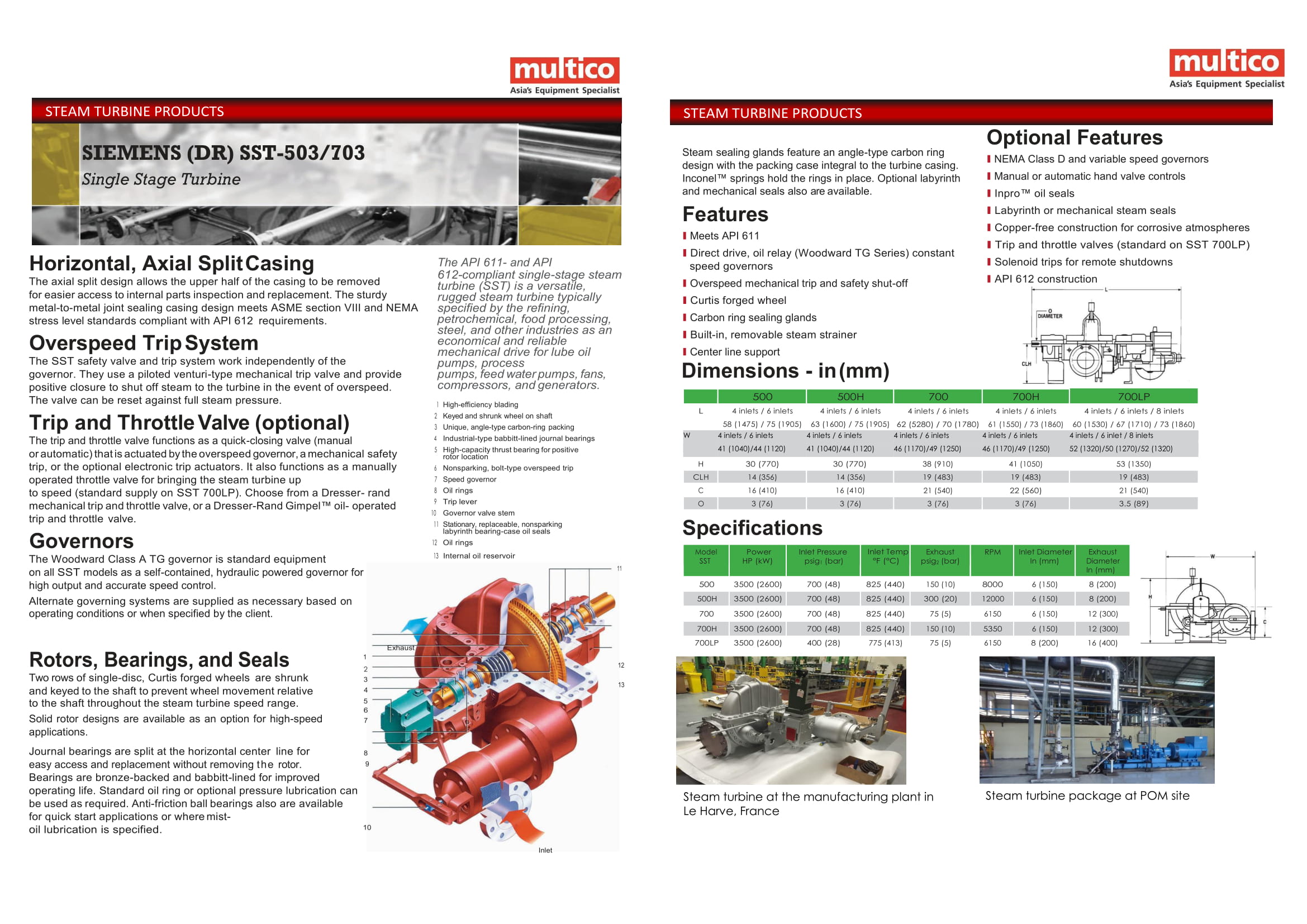

The steam turbine has the specialty of horizontal Axial Split Casing, Overspeed Trip System, Trip and Throttle Valve (Optional), Governors, Rotors, Bearings, and Seals. The upper half of the casing it can be removed with the axial split design for easier access to internal parts inspection and replacement. The casing design is a sturdy metal-to-metal joint sealing casing that meets the NEMA stress level standards-compliant with API 612 requirements and ASME section VIII.

The SST safety valve and trip system work independently of the governor. They use a piloted venturi-type mechanical trip valve and provide positive closure to shut off the steams from flowing to the turbine in the event of over speed. The valve can be reset against full steam pressure.

The trip and throttle valve function as a quick-closing valve (manual or automatic) that is actuated by the Overspeed governor, a mechanical safety trip, or the optional electronic trip actuators. It is also a method to manually operate the throttle valve to accelerate the steam turbine up to speed (standard supply on SST 700LP). Select from a Dresser-Rand Gimpel™ oil- operated trip and throttle valve or a Dresser-Rand mechanical trip and throttle valve.

The Woodward Class A TG governor is standard equipment on all SST models as a self-contained, hydraulic-powered governor for high output and accurate speed control. Alternate governing systems can be supplied to the client based on request or according to the necessity of operating conditions.

In order to prevent wheel movement relative to the shaft throughout the steam turbine speed range, two rows of single-disc, Curtis forged wheels are shrunk and keyed to the shaft. For high-speed applications, solid rotor designs are available as an option. For easy access and replacement, journal bearings are split at the horizontal centerline without removing the rotor. To improve its operating life bearings are bronze-backed and babbitt-lined and optional pressure lubrication or standard oil ring can be used if necessary. Anti-friction ball bearings are inserted for oil mist lubrication specificated area and quick start applications.

The steam turbine has the specialty of horizontal Axial Split Casing, Overspeed Trip System, Trip and Throttle Valve (Optional), Governors, Rotors, Bearings, and Seals. The upper half of the casing it can be removed with the axial split design for easier access to internal parts inspection and replacement. The casing design is a sturdy metal-to-metal joint sealing casing that meets the NEMA stress level standards-compliant with API 612 requirements and ASME section VIII.

The SST safety valve and trip system work independently of the governor. They use a piloted venturi-type mechanical trip valve and provide positive closure to shut off the steams from flowing to the turbine in the event of over speed. The valve can be reset against full steam pressure.

The trip and throttle valve function as a quick-closing valve (manual or automatic) that is actuated by the Overspeed governor, a mechanical safety trip, or the optional electronic trip actuators. It is also a method to manually operate the throttle valve to accelerate the steam turbine up to speed (standard supply on SST 700LP). Select from a Dresser-Rand Gimpel™ oil- operated trip and throttle valve or a Dresser-Rand mechanical trip and throttle valve.

The Woodward Class A TG governor is standard equipment on all SST models as a self-contained, hydraulic-powered governor for high output and accurate speed control. Alternate governing systems can be supplied to the client based on request or according to the necessity of operating conditions.

In order to prevent wheel movement relative to the shaft throughout the steam turbine speed range, two rows of single-disc, Curtis forged wheels are shrunk and keyed to the shaft. For high-speed applications, solid rotor designs are available as an option. For easy access and replacement, journal bearings are split at the horizontal centerline without removing the rotor. To improve its operating life bearings are bronze-backed and babbitt-lined and optional pressure lubrication or standard oil ring can be used if necessary. Anti-friction ball bearings are inserted for oil mist lubrication specificated area and quick start applications.

Suitable to be a mechanical drive for lube oil pumps, process pumps, feed water pumps, fans, compressors, generators, etc.

Steam Turbine

Gearbox, Alternator

• 500

• 500H

• 700

• 700H

• 700LP

• Spare parts

| Feature | Performance |

|---|---|

| Durable | Curtis forged wheel, Carbon ring sealing glands |

| Safety device | Overspeed mechanical trip and safety shut-off |

| Constant Performance | Direct drive, oil relay (Woodward TG Series) constant speed governors |

| Specification | Properties |

|---|---|

| Power HP (kW) | 3500(2600) |

| Inlet Pressure psig1 (bar) | 500 : 700 (48) 500H : 700 (48) 700 : 700 (48) 700H : 700 (48) 700LP : 400 (28) |

| Inlet Temp °F(°C) | 500 : 825 (440) 500H : 825 (440) 700 : 825 (440) 700H : 825 (440) 700LP : 775 (413) |

| Exhaust psig2 (bar) | 500 : 150 (10) 500H : 300 (20) 700 : 75 (5) 700H : 150 (10) 700LP : 75 (5) |

| RPM | 500 : 8000 500H : 12000 700 : 6150 700H : 5350 700LP : 6150 |

| Inlet Diameter In (mm) | 500 : 6 (150) 500H : 6 (150) 700 : 6 (150) 700H : 6 (150) 700LP : 8 (200) |

| Exhaust Diameter In (mm) | 500 : 8 (200) 500H : 8 (200) 700 : 12 (300) 700H : 12 (300) 700LP : 16 (400) |

| Length in (mm) | 500 : 4 inlets / 6 inlets, 58 (1475) / 75 (1905) 500H : 4 inlets / 6 inlets, 63 (1600) / 75 (1905) 700 : 4 inlets / 6 inlets, 62 (1575) / 70 (1780) 700H : 4 inlets / 6 inlets, 61 (1550) / 73 (1860) 700LP : 4 inlets / 6 inlets / 8 inlets, 60 (1530) / 67 (1710) / 73 (1860) |

| Width in (mm) | 500 : 4 inlets / 6 inlets, 41 (1040) / 44 (1120) 500H : 4 inlets / 6 inlets, 41 (1040) / 44 (1120) 700 : 4 inlets / 6 inlets, 46 (1170) / 49 (1250) 700H : 4 inlets / 6 inlets, 46 (1170) / 49 (1250) 700LP : 4 inlets / 6 inlets / 8 inlets, 52 (1320) / 50 (1270) / 52 (1320) |

| Height in (mm) | 500 : 30 (770) 500H : 30 (770) 700 : 38 (910) 700H : 41 (1050) 700LP : 53 (1350) |

| CLH in (mm) | 500 : 14 (356) 500H : 14 (356) 700 : 19 (483) 700H : 19 (483) 700LP : 19 (483) |

| C (mm) | 500 : 16 (410) 500H : 16 (410) 700 : 21 (540) 700H : 22 (560) 700LP : 21 (540) |

| O (mm) | 500 : 3 (76) 500H : 3 (76) 700 : 3 (76) 700H : 3 (76) 700LP : 3.5 (89) |

NA

NA

NA

| Company | Installation | Minimum Order | Cover area |

|---|---|---|---|

| (Steam Turbine Supplier) | Yes | 0 | Cyberjaya, Johor, Kedah, Kelantan, Kuala Lumpur, Malacca, Negeri Sembilan, Pahang, Penang, Perak, Perlis, Putrajaya, Selangor, Terengganu |

| No Result found. | |||

No Photo & Brochure available