Aathaworld Aluminium

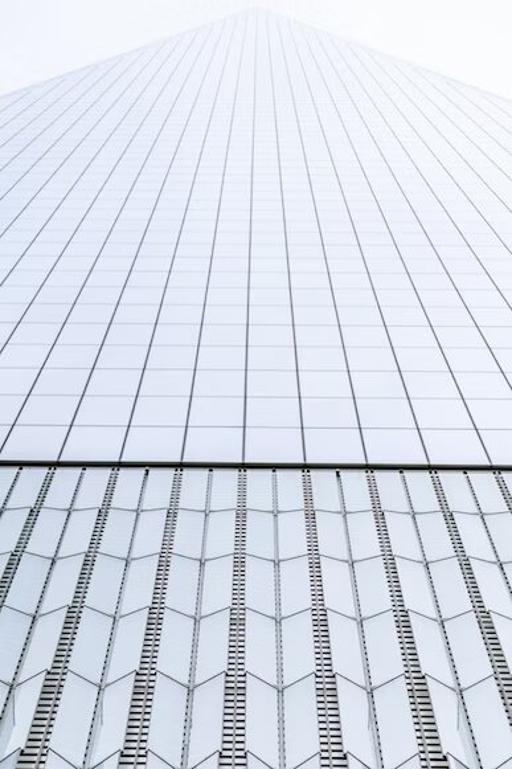

Aathaworld Aluminium offers expert supply and installation services for a wide range of aluminium products, including aluminium coil, sheet, chequered plate, pipe, roofing, composite panels, wall cladding, and more. Our comprehensive product line meets diverse project requirements with high-quality finishes.

• Lightweight

• Long-lasting

• Multiple Dimension

Builtory Supplier Products

100+

1000+