B Grade Fireproof Aluminium Composite Panel Alucoone

Alucoone B grade fireproof aluminum composite panel is a type of construction material developed according to the needs of higher fireproof function. It is is a kind of green material which does not produce harmful gases when get burned. The product is composed of two fireproof aluminum layer, fireproof plastic core, and adhesive polymeric membrane. Alucoone B fireproof Aluminum Composite Panel reaches the high-level fire-rating standards of different countries and retains the advantages of flatness, formability, weather ability, easy installation etc. Our company keeps improving the technologies during the time and cooperates closely with Chinese well-know fireproof plastic core suppliers so that we have developed the new type of B high fire-retardant aluminum composite panel whose calorific value is below 12. It meets the requirements of China National Standard calorific value of B grade fireproof Aluminum Composite Panel. At present, the B grade fireproof aluminum composite pane! manufacturers in China mostly adopt two types of core material system: the aluminum hydroxide and the magnesium hydroxide system. Alucoone B fireproof aluminum composite pane! uses the mixture of magnesium hydroxide and Polyethylene as the core material, which is developed along with the China National Geology and mineral Institute. The outstanding technology research and development group guarantees stability and reliability of the products.

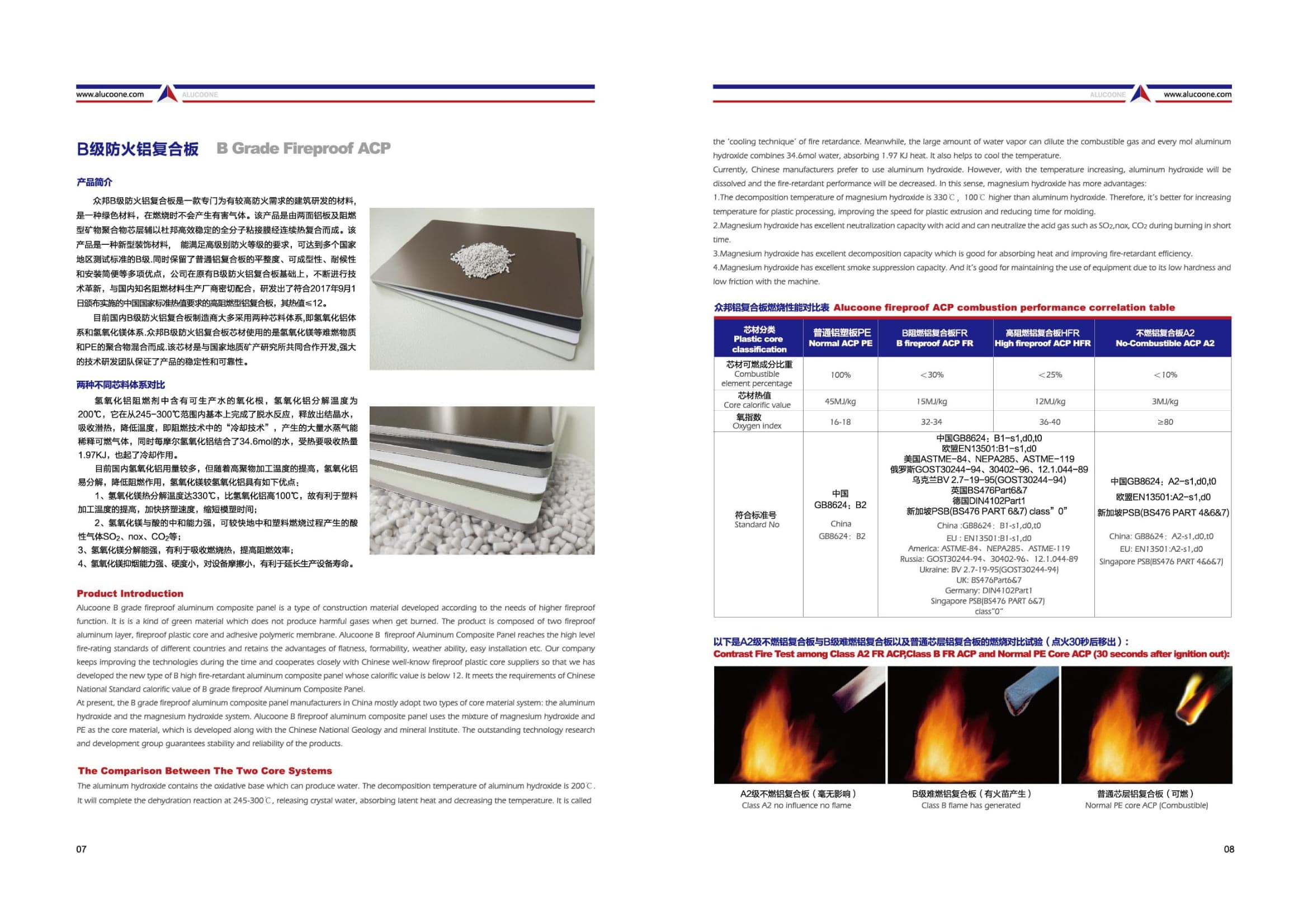

The aluminum hydroxide contains the oxidative base which can produce water. The decomposition temperature of aluminum hydroxide is 200°C. It will complete the dehydration reaction at 245-300 C, releasing crystal water, absorbing latent heat and decreasing the temperature. A large amount of water vapor can dilute the combustible gas and every mol aluminum hydroxide combines 34.6mol water, absorbing 1.97 KJ heat. It also helps to cool the temperature. Currently, Chinese manufacturers prefer to use aluminum hydroxide. However, when the temperature rises to a certain point, aluminum hydroxide will be dissolved and the fire-retardant properties will be decreased. In this sense, magnesium hydroxide has more advantages. The decomposition temperature of magnesium hydroxide is 330° C, 100°C higher than aluminum hydroxide. Therefore, it's high temperature are better for plastic processing, which improves the speed of plastic extrusion and reducing the time for molding. Magnesium hydroxide has excellent neutralization capacity towards acid and can neutralize the acid gas such as SO2, NOx, CO2 during burning in a short time. Magnesium hydroxide has excellent decomposition capacity that allows it better for absorbing heat and improving fire-retardant efficiency. Magnesium hydroxide has excellent smoke suppression capacity. It has low hardness and low friction as a piece of equipment that allows it to have a longer lifespan.

The aluminum hydroxide contains the oxidative base which can produce water. The decomposition temperature of aluminum hydroxide is 200°C. It will complete the dehydration reaction at 245-300 C, releasing crystal water, absorbing latent heat and decreasing the temperature. A large amount of water vapor can dilute the combustible gas and every mol aluminum hydroxide combines 34.6mol water, absorbing 1.97 KJ heat. It also helps to cool the temperature. Currently, Chinese manufacturers prefer to use aluminum hydroxide. However, when the temperature rises to a certain point, aluminum hydroxide will be dissolved and the fire-retardant properties will be decreased. In this sense, magnesium hydroxide has more advantages. The decomposition temperature of magnesium hydroxide is 330° C, 100°C higher than aluminum hydroxide. Therefore, it's high temperature are better for plastic processing, which improves the speed of plastic extrusion and reducing the time for molding. Magnesium hydroxide has excellent neutralization capacity towards acid and can neutralize the acid gas such as SO2, NOx, CO2 during burning in a short time. Magnesium hydroxide has excellent decomposition capacity that allows it better for absorbing heat and improving fire-retardant efficiency. Magnesium hydroxide has excellent smoke suppression capacity. It has low hardness and low friction as a piece of equipment that allows it to have a longer lifespan.

NA

Sandwich Panel

Aluminium alloy, Low Density Polyethylene (LDPE), Polyvinylidene Fluoride (PVDF), Magnesium Hydroxide

• 2000mm(L) x 1220mm(W) x 4mm(T)

• 2440mm(L) x 1250mm(W) x 4mm(T)

• 3000mm(L) x 1500mm(W) x 4mm(T)

• 3200mm(L) x 2030mm(W) x 4mm(T)

• Customize

| Feature | Performance |

|---|---|

| Waterproof | Yes |

| Corrosion resistant | Yes |

| Impact resistant | Yes |

| Fire resistant | Yes |

| Damp Proof | Yes |

| Sound insulation | Yes |

| Thermal insulation | Yes |

| Specification | Properties |

|---|---|

| Combustible element percentage | <30% |

| Core calorific value | 15MJ/kg |

| Oxygen index | 32-34 |

NA

NA

NA

| Company | Installation | Minimum Order | Cover area |

|---|---|---|---|

| (Supplier and Contractor) | Yes | 0 | Cyberjaya, Johor, Kedah, Kelantan, Kuala Lumpur, Labuan, Malacca, Negeri Sembilan, Pahang, Penang, Perak, Perlis, Putrajaya, Sabah, Sarawak, Terengganu |

| No Result found. | |||

No Photo & Brochure available