Vertical Panel Saw Machine | ACP Cutting and Grooving Machine Dynamic Machines Services

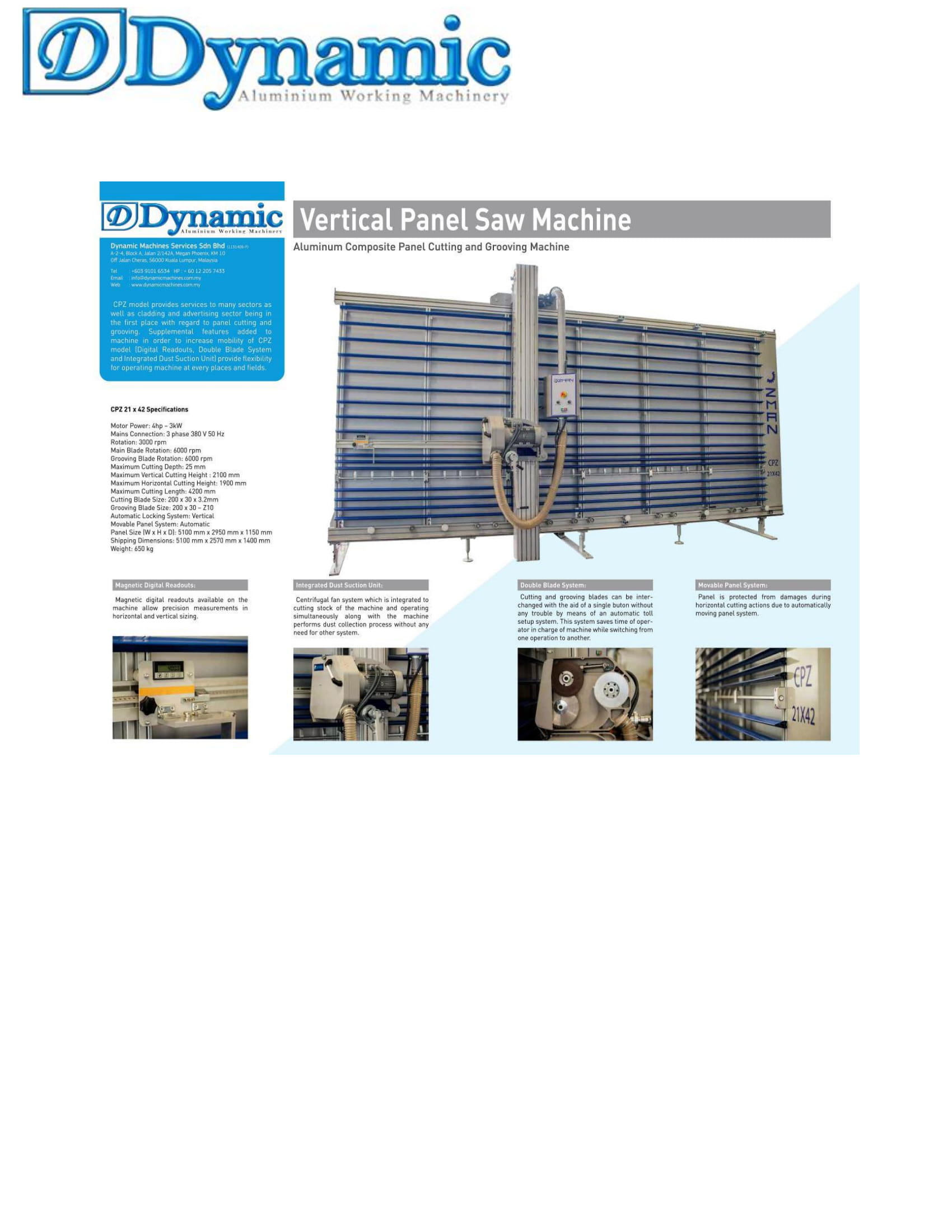

Vertical Panel Saw Machine (CPZ 21x42 model) is an Aluminium Composite Panel (ACP) Cutting and Grooving Machine. ACP is a type of flat panel which 2 layers of thin Aluminium sheets are bonded with an inner layer of non-Aluminium core, nowadays it is widely used at facades of buildings, signage and insulation. With our machine, ACP can be cut and grooved into various size to match the exact dimension to ease the installation process.

This machine has various functions. Magnetic Digital Readouts allow precision measurement for horizontal and vertical sizing. In their Integrated Dust Suction Unit, a Centrifugal fan system is integrated to cutting stock of the machine and operating simultaneously along with the machine performs dust collection process without any need for other system. They have a Double Blade System, which its cutting and grooving blades can be interchanged with the aid of a single button without any trouble by means of an automatic toll setup system. This system saves time of operator in charge of machine while switching from one operation to another. Last, is its Movable Panel System. In this system, the panel is protected from damages during horizontal cutting actions due to automatically moving panel system.

This machine has various functions. Magnetic Digital Readouts allow precision measurement for horizontal and vertical sizing. In their Integrated Dust Suction Unit, a Centrifugal fan system is integrated to cutting stock of the machine and operating simultaneously along with the machine performs dust collection process without any need for other system. They have a Double Blade System, which its cutting and grooving blades can be interchanged with the aid of a single button without any trouble by means of an automatic toll setup system. This system saves time of operator in charge of machine while switching from one operation to another. Last, is its Movable Panel System. In this system, the panel is protected from damages during horizontal cutting actions due to automatically moving panel system.

Vertical Panel Saw Machine (CPZ 21x42 model) provides services to many sectors as well as cladding and advertising sector being in the first place with regard to panel cutting and grooving. Supplemental features added to machine in order to increase mobility of CPZ model (Digital Readouts, Double Blade System and Integrated Dust Suction Unit) provide flexibility for operating machine at every places and fields.

Cutting Machine

Electric motor

NA

| Feature | Performance |

|---|---|

| High Precision | Magnetic Digital Readouts Allow precision measurement for horizontal and vertical sizing |

| Automation | The centrifugal fan system is integrated into cutting stock of the machine and operating simultaneously along with the machine performs dust collection process without any need for other system |

| Versatile | Double Blade System cutting and grooving blades can be interchanged with the aid of a single button without any trouble by means of an automatic toll setup system. This system saves the time of an operator in charge of a machine while switching from one operation to another. |

| Safety device | Movable Panel System is protected from damages during horizontal cutting actions due to automatically moving panel system |

| Specification | Properties |

|---|---|

| Motor Power | 4hp - 3kW |

| Mains Connection | 3 phase 380V 50Hz |

| Rotation | 3000rpm |

| Main Blade Rotation | 6000rpm |

| Grooving Blade Rotation | 6000rpm |

| Maximum Cutting Depth | 25mm |

| Maximum Vertical Cutting Height | 2100mm |

| Maximum Horizontal Cutting Height | 1900mm |

| Maximum Cutting Length | 4200mm |

| Cutting Blade Size | 200 x 30 x 3.2mm |

| Grooving Blade Size | 200 x 30 - Z10 |

| Automatic Locking System | Vertical |

| Movable Panel System | Automatic |

| Panel Size (W x H x D) | 5100mm x 2950mm x 1150mm |

| Shipping Dimensions | 5100mm x 2570mm x 1400mm |

| Weight | 650kg |

NA

NA

NA

| Company | Installation | Minimum Order | Cover area |

|---|---|---|---|

| (Aluminium Fabrication Machine Supplier) | Yes | 0 | Cyberjaya, Johor, Kedah, Kelantan, Kuala Lumpur, Malacca, Negeri Sembilan, Pahang, Penang, Perak, Perlis, Putrajaya, Selangor, Terengganu |

| No Result found. | |||

No Photo & Brochure available