Multico Enviro (M) Sdn Bhd

About Us

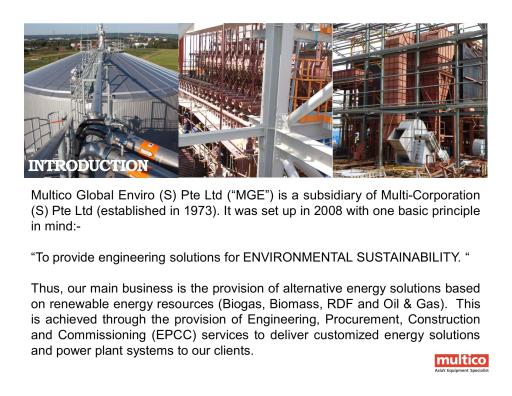

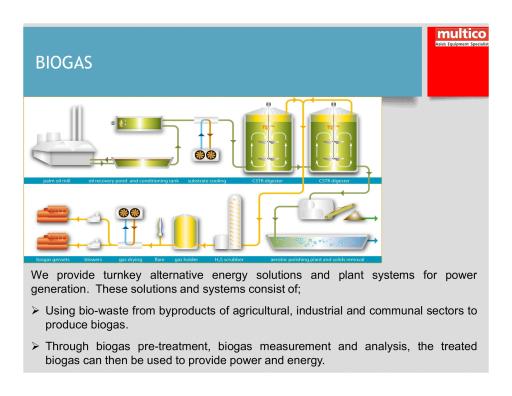

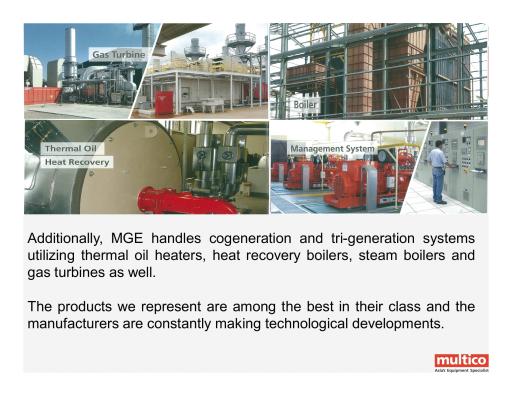

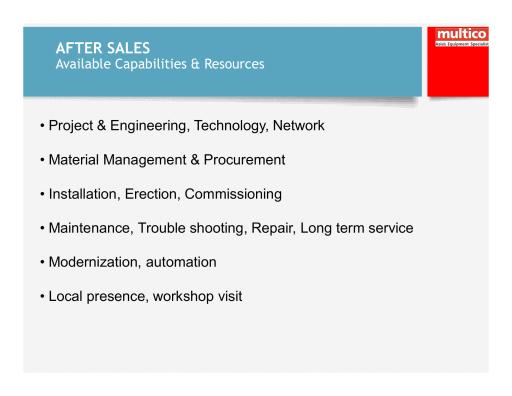

Multico Enviro (M) Sdn Bhd is the subsidiary company of Multico Global Enviro Pte Ltd that is located in Singapore. Multico Global Enviro Pte Ltd is also the subsidiary of Multi-Corporation Pte Ltd and its main business is the provision of alternative energy solutions based on renewable energy resources such biogas, biomass, RDF, Oil & Gas, etc. The company is the business partner and packager for Steam Turbine Solutions and Biogas Engine Gensets and it offers Steam Turbine solutions ranging from 50kW to 25MW for power plants, waste to energy. The regional hub in Malaysia also provides sales, proposals and after-sales support including engineering and various power generation solutions.

Gallery

Featured Product Brands

Multico Enviro (M) Sdn Bhd Products

Builtory Supplier Products

1000+

1000+

1000+