Material

Brass

Sep 18 2020

Brass is widely applied to many sectors, from retail, industrial, commercial to construction. It has a relatively gold colour and bright appealing outlook. Although it can be presented in a silvery-white or reddish-gold, by adjusting the composition of all of their internal elements will decide the difference. For instance, putting in more of zinc will make silver-alloy while rosy colour toning can be done through the better ratio of copper. Brass has better malleability compared to zinc as well as bronze. Many musical instrumental tools use brass as their core material because it has a high level of properties in term of acoustic. Furthermore, the frictional of this metal is quite low too. Sparking will not be happening too often and therefore, suitable for machining works where lowered chance to sparking material is needed.

In addition, the heat energy used for this alloy for workability requires lesser than other, since it has a melting point that is comparably low while it conducts heat and transfers them easier than other products. In regards to semi or finished product, brass can actually be not tolerating towards corrosion and hence, it is a very corrosive-resistant partner that can be used in saltwater through proper treatment (for instance, galvanic corrosion can be resisted). As per mentioned, the casting ability of brass also makes it an attractive point to be used in any scenarios since its malleability is relatively convenient. Since brass like other metals, can be recycled and reproduced into other economically sound products, its non-ferromagnetic attribute makes it simpler to carry on separation when mingling with other metal wastes.

In addition, the heat energy used for this alloy for workability requires lesser than other, since it has a melting point that is comparably low while it conducts heat and transfers them easier than other products. In regards to semi or finished product, brass can actually be not tolerating towards corrosion and hence, it is a very corrosive-resistant partner that can be used in saltwater through proper treatment (for instance, galvanic corrosion can be resisted). As per mentioned, the casting ability of brass also makes it an attractive point to be used in any scenarios since its malleability is relatively convenient. Since brass like other metals, can be recycled and reproduced into other economically sound products, its non-ferromagnetic attribute makes it simpler to carry on separation when mingling with other metal wastes.

There are comparisons can be made among different materials, such as bronze and copper to brass. Layman wise, they look similar in term of classification as the metal of "red". Original identical does not mean to be having exertion of proper functional attributes to fit the required needs. For instance, brass is the part of alloy that made up of zinc with copper, the variation in the elements such as zinc addition make the difference just like other end products. It has the ability to be manufactured in the form of various colours, properties that are ranged in wide possibilities. Zinc's measure in this material can enhance the ductility as well as its strength from many aspects. The colours can be comprised of examples such as yellow, red to in between and it is highly dependable to the zinc element contribution to the general alloy.

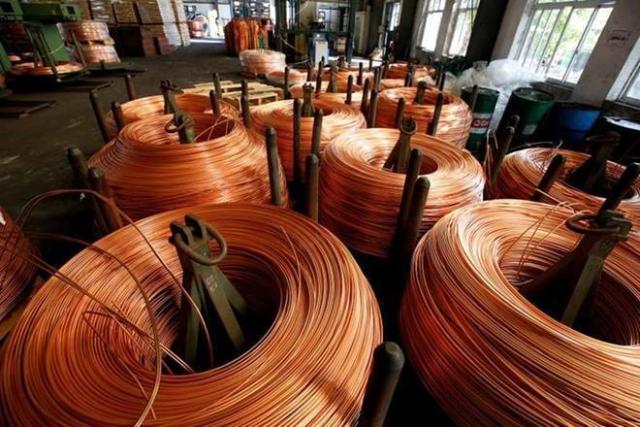

On the other hand, copper is another popular product that is always being used to compare from the characteristics of strength, corrosion resistance, formability, thermal and electrical conductivity. While scientist found out that copper is doing a great job in all of these qualities. Its qualities included also easily to be polished, buffered to huge lustre and texture that seem to be preferable to the end-user. At the same time, brazing and soldering are always can be prepared with welding potential. They can be welded through methods such as resistance, arc or other gases. Copper can be a good bacteria fighter and suitable to be used in an industrial application that require a high level of effectiveness in term of antimicrobial. One of the earliest metals found and developed by a human, while applied extensively in water purification, wound sterilization, wiring and other electrical products.

On the other hand, copper is another popular product that is always being used to compare from the characteristics of strength, corrosion resistance, formability, thermal and electrical conductivity. While scientist found out that copper is doing a great job in all of these qualities. Its qualities included also easily to be polished, buffered to huge lustre and texture that seem to be preferable to the end-user. At the same time, brazing and soldering are always can be prepared with welding potential. They can be welded through methods such as resistance, arc or other gases. Copper can be a good bacteria fighter and suitable to be used in an industrial application that require a high level of effectiveness in term of antimicrobial. One of the earliest metals found and developed by a human, while applied extensively in water purification, wound sterilization, wiring and other electrical products.

Other brass products are common to be seen of application, such as for decoration usage since it is a good alternative in term of appearance to gold when the budget is tight. Safer to use brass too as compared to luxury gold because it will attract theft. Moreover, durability and easy-to-work features of brass, make it superior for your ideal musical instrument. Further in elaborating the functionality of widened brass usefulness, it can also be fabricated to medal (one of the brass alloys), since it can seem to be tertiary after the quality of gold and silver in term of appearance (putting aside the real value of it in term of market perception and trading). Decorative while bring out the authentically feel of brass, is a strong point for people who go for brass.

In addition, the dull-gold colour of bronze that derived from brass alloy is widely put in the construction and architectural purposes. For instance, many sculptures that we can see in the market are made up of bronze. It has been further developed into the heavier industrial sectors, including manufacturing of bearings and bushings. The reason it is suitable for these fittings and accessories mainly due to the low metal friction level, while its resistant against corrosion is another point to save maintenance and replacement cost. Many other brass alloys that are popular in cross-sectors too, such as tin brass, phosphor bronze, aluminium bronze, nickel-brass (also known as nickel silver that is widely seen in optical and food industries), copper-nickel and silicon bronze

In addition, the dull-gold colour of bronze that derived from brass alloy is widely put in the construction and architectural purposes. For instance, many sculptures that we can see in the market are made up of bronze. It has been further developed into the heavier industrial sectors, including manufacturing of bearings and bushings. The reason it is suitable for these fittings and accessories mainly due to the low metal friction level, while its resistant against corrosion is another point to save maintenance and replacement cost. Many other brass alloys that are popular in cross-sectors too, such as tin brass, phosphor bronze, aluminium bronze, nickel-brass (also known as nickel silver that is widely seen in optical and food industries), copper-nickel and silicon bronze

Advantage of Brass

Workability

Attractive Outlook

Corrosion Resistance

Thermal Conductivity

Durability

Conductive to Electrics

Applications

Contact us today for your Brass Materials in Malaysia.