Material

Acrylic

Apr 28 2022

Acrylic or acrylic glass is also known by its trade name Crylux, Plexiglas, Perspex, Acrylite, and Lucite or the scientific name Polymethyl Methacrylate(PMMA). The acrylic is a transparent plastic that often uses as the replacement for glass as it has characteristics of lightweight and also shatterproof. The material can also be used as a casting resin to make waterproofing, translucent effect, etc. Some modern painting can be found contain acrylic as the acrylic doesn't dissolve in a humid environment and hence able to protect the painting.

Introduction

Acrylic glass has the characteristic of high transparency, high tensile strength, high flexibility, polishable, heat and chemical resistance, and UV tolerance. Although most acrylic glass tends to be brittle when under high impact force but the material itself is much more light and stronger than most glass and able add color and texture to the surface. When the acrylic glass surface contains any scratches it would only need a simple polish and the scratch will be gone. Furthermore, acrylic is more favorable to be export since is stronger than glass and lesser in weight which is very ideal for e-commerce.Applications

Since glass also contains a higher grade type which is the tempered glass, so comparing acrylic glass with tempered glass would have a clearer picture. Tempered glass is normally produced in desired shape and size. If there are any changes of shape after produce would usually shatter the glass(unless it special treated) but on the other hand acrylic glass on after produced still can be cut in different shape and sizes with circular saws, routers, and also a little extra careful. Moreover, most tempered glasses are usually 2 times heavier if the size is the same as acrylic glass and this causes the transport fee to be more expensive too. In terms of temperature withstands, tempered glass would be much better since acrylic is rubber material and anything beyond normal weather temperature would cause damage to it. Without a certain lamination, acrylic tends to break in big pieces and eventually much more danger when broken while tempered glass is much safer because when it broke it shatters becomes smaller pieces of glass and hardly be any serious injury. Both this glasses have their drawback and benefits so choosing the usage place will be much wiser. Acrylic would be better on balcony barriers, window, billboards, as well as display glasses for commercial use. Whereas tempered glass is much safer for indoor like showers door glass, mirrors, oven, microwave, etc. Another material for making replacement glass is the polycarbonate which is also a transparent plastic glass. Both also have their benefits and drawbacks. Acrylic is shinier and less expensive but lower impact resistant vice versa the polycarbonate glass high in impact resistant but higher in price and easier to scratch. Eventually, both materials are also light in weight and stronger than most of the glass. In certain conditions, they are both used up to build on the same product with a different purpose-for example the windshield of a small aircraft is used acrylic and the aircraft door is use polycarbonate. Other similar materials are polyethylene, polypropylene, polystyrene, polyesters, polycarbonate, PVC, Nylon, etc.

Often acrylic is more than just glass, itself can act as an additive to oils and fluids so that these fluid don't get vicious in the cold-for example, the heavy equipment that uses oils for hydraulic fluid able to operate down to -100C(-150F). Another is the Acrylic coating or acrylic waterproofing that is growing in popularity. Major house and a building roofing are turning to acrylic coating since it is designed to be more environmentally friendly, better weather resistant and also reduce UV exposure. The acrylic coating is a relatively easy method since they are a single component, waterborne material that does not require any sort of double component mixing like an epoxy. All you need to do is use it like normal paint for your house and added bonus for acrylic coating is that they are usually low VOC and limited level of toxicity so that's why it much more Eco-friendly. The acrylic coating is usually shinier and glossier than many coating as this characteristic are used for reflective UV and also avoid fluctuate temperature that might save your energy cost over the long haul. Similar coating or waterproofing usage is the polyurethane(PU) coating. Both of this coating has many similarities and might perform better than the another. Generally, acrylic coating is better in UV resistant and environmental friendly while PU coating is more resistance to high traffic flow and more durable. Both prices are incomparable since different country or region might different in material cost and labor cost in different time. So choosing the specification that suits your need is much more important for example, roof waterproofing would you choose a high traffic resistance or UV resistance? If the price is not big different than your answer will be obvious.

Advantages

Acrylic product usually has the following advantages:Light Weight

High Weather Resistance

High transparency

Easy to maintain

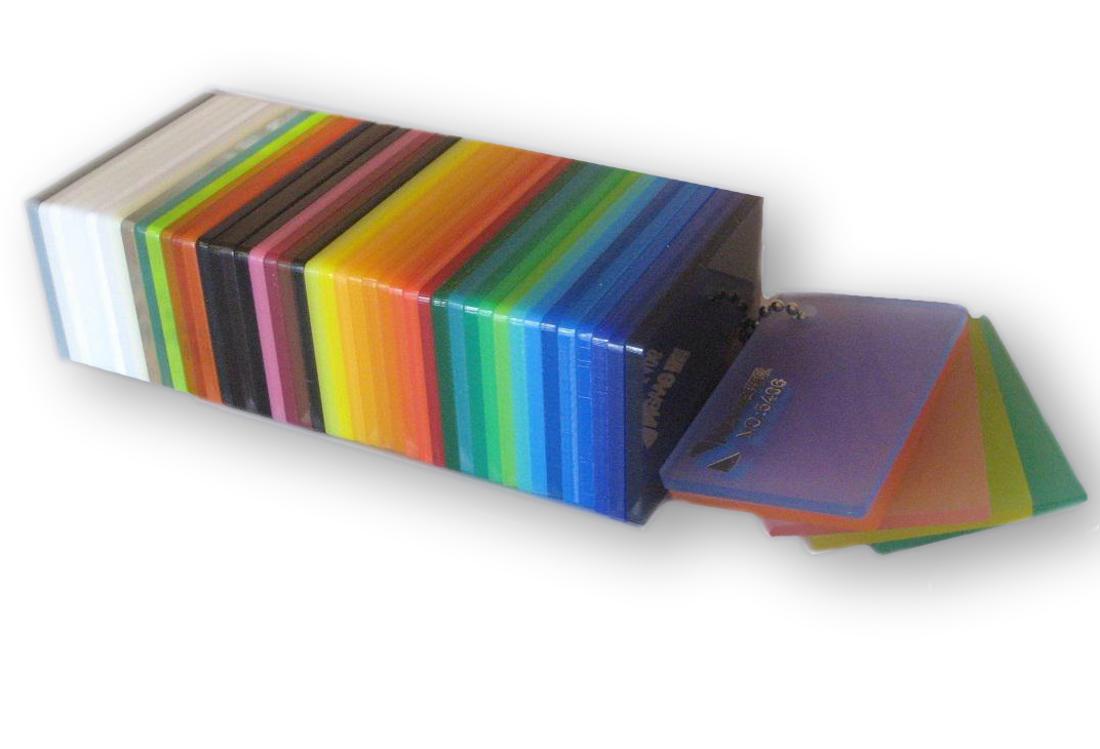

Acrylic products

Acrylic solid products:Acrylic Board

Acrylic Box

Acrylic Stand

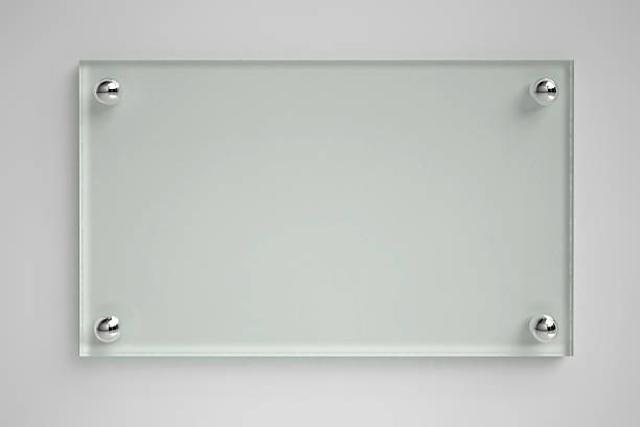

Acrylic Sign

Acrylic Rod & Tube

Acrylic Mirror

Acrylic coating products:

Acrylic Waterproofing Membrane

Acrylic Emulsion Waterproofing Coating

Acrylic Elastomeric Waterproofing Coating

When choosing acrylic for any application, pricing should not always be the first justification. One must consult its material professional for its best usage and safety since there is no one solution that works on all things.

Contact us today for your acrylic supplier or contractor in Malaysia.