Material

Polycarbonate Sheet

Aug 30 2020

Polycarbonate is one of the plastics that can offer superiority in resistance against electrical, heat, water and more. At the same time, its stability in the shape, size, pattern are in aligned with its toughness and malleability. Furthermore, it brings no heavy burden to many buildings in term of structural due to its lightweight-to-size ratio while did not compromising the strength when compare it with a similar product. Nevertheless, the balancing of all properties makes it wins over all the other types within the same breakdown for optimal material. Many of the facade designs will apply polycarbonate sheet as their priority due to its leading transparency, or at least the premium clarity from the optical aspect. It is lowering down the cost of the building when bills of electricity are concerned, as a preferred layer for insulating.

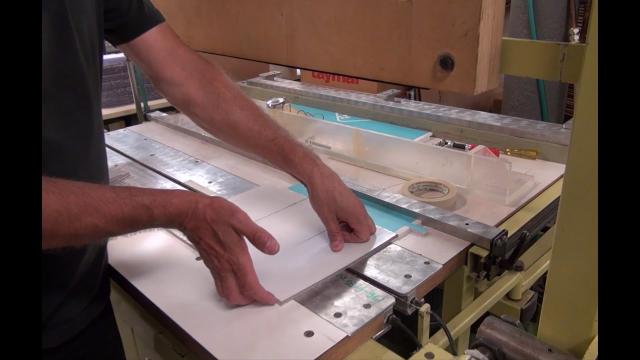

There are several ways to bend majority of polycarbonate in the production factory, these are inclusive of hotline bending for instance; bending technique that involves heating it up, very suitable to be applied on sheet bending that is thicker. Polycarbonate has a high viscosity, and therefore the processing will make sure the reading can be reduced. The polymer will be heated up to carry on melting into the pre-set mould at relatively high temperature, cooling thereafter will then complete the intended properties and its shape. Ordinary polycarbonate sheet will basically be having a hundred seventy celcius to two hundred and twenty-five celcius for vacuum forming and mechanical forming, pre-heating is on the other hand at the clamping frame is recommended to be ranged from one hundred twenty to one hundred and thirty celcius.

There are several ways to bend majority of polycarbonate in the production factory, these are inclusive of hotline bending for instance; bending technique that involves heating it up, very suitable to be applied on sheet bending that is thicker. Polycarbonate has a high viscosity, and therefore the processing will make sure the reading can be reduced. The polymer will be heated up to carry on melting into the pre-set mould at relatively high temperature, cooling thereafter will then complete the intended properties and its shape. Ordinary polycarbonate sheet will basically be having a hundred seventy celcius to two hundred and twenty-five celcius for vacuum forming and mechanical forming, pre-heating is on the other hand at the clamping frame is recommended to be ranged from one hundred twenty to one hundred and thirty celcius.

Taking glass as a comparison against polycarbonate, it will have some similarities as well as non-identical points for choice evaluation. For instance, without further treating the glass properties and polycarbonate will take over its insulation characteristics by having ordinary material. This is essential for high-rise buildings that have no trees as shading and expose to a lot of hot sunlight during the daytime, of course, it does apply to landed low-rise that requires such a feature. A further point on the hand, its transparency will also save up a lot of costs to building operator since you no longer require so much of manmade lighting to be switched on, while the heating value from the natural lights is also being reduced through the insulating function. Its retention of coolness from the air-conditioned room is also mitigating the risk of cold air being wasted out from your building.

More to our discussion is that glazing security light or even the skylight design can be done from using polycarbonate installation, as an alternative to the product of glass. Glass on the other hand, is heavier and not benefiting the structural design as well as its associated cost to strengthen it. Especially when taking a renovation as an example for upgrading works, homeowners are definitely a group of customers who gain a direct advantage by simple costing calculation; commercial building quantity surveyor finds its scalable advantages are far more developed and obvious when using it for their customers for budget purpose, due to the economies of scale for project size. Polycarbonate is also having higher impact resistance, as good as two hundred times than conventional glass while its lightweight can get an installer to do it quicker and cheaper.

More to our discussion is that glazing security light or even the skylight design can be done from using polycarbonate installation, as an alternative to the product of glass. Glass on the other hand, is heavier and not benefiting the structural design as well as its associated cost to strengthen it. Especially when taking a renovation as an example for upgrading works, homeowners are definitely a group of customers who gain a direct advantage by simple costing calculation; commercial building quantity surveyor finds its scalable advantages are far more developed and obvious when using it for their customers for budget purpose, due to the economies of scale for project size. Polycarbonate is also having higher impact resistance, as good as two hundred times than conventional glass while its lightweight can get an installer to do it quicker and cheaper.

Acrylic has also relatively high popularity as to polycarbonate, therefore, it is worthy to make a simple comparison between both of them. First of all, acrylic is divided into basically few shapes, from an acrylic rod, acrylic tube, acrylic sheet and more. At the same time, acrylic is widely used in most of the retail in addition to commercial and industrial, while construction materials use mostly the polycarbonate. Acrylic is being applied as windshield, instrument panel, the window when it goes to the automotive and transportation sectors while building installation would be more towards lighting, its fixtures, canopies as well as wall to windows. There are some advantages of applying acrylic instead of glass, such as twice as light as glass but having about thirty times in term of strength.

However, although acrylic is having durability and safety features while it is also less costly, convenience to install than glass; but, it is not as an-scratching as glass while its resistance against heat is not so good. It can be translucent while maintenance cost is also lower, yet, polycarbonate is somewhere falling in between, balancing both of the characteristics obtainable from the glass as well as acrylic, while supplementing their weaknesses. For instance, polycarbonate tends to be more impact resistance than acrylic, while polycarbonate is more suitable for outdoor use in which acrylic tends to lose this attribute. Of course, at the end of any material selection stories, the properties, suitability, budget and other potential characteristics shall be within the list of consideration before making a decision.

However, although acrylic is having durability and safety features while it is also less costly, convenience to install than glass; but, it is not as an-scratching as glass while its resistance against heat is not so good. It can be translucent while maintenance cost is also lower, yet, polycarbonate is somewhere falling in between, balancing both of the characteristics obtainable from the glass as well as acrylic, while supplementing their weaknesses. For instance, polycarbonate tends to be more impact resistance than acrylic, while polycarbonate is more suitable for outdoor use in which acrylic tends to lose this attribute. Of course, at the end of any material selection stories, the properties, suitability, budget and other potential characteristics shall be within the list of consideration before making a decision.