Material

Fibreglass

Aug 5 2020

Fibreglass might be confused with another material, called as FRP (Fiber-reinforced plastic) in the market, but they are both different materials and meaning. FRP might not be using fibreglass since it can apply cellulose fibres or carbon to substitute it. Fibres will be organized without a proper pattern, can be claimed as a random form which is woven into fabric or being flattening to form chopped strand mat (also addressed as a sheet). In the construction industry as well as the production sector, FRP application seems to be popular as its durability is undoubtedly advantaged by its light in body weight while the properties are robust. At the same time, the strength-to-weight ratio is relatively attractive as in, they can do up to seven times better than steel. Comparing it to other materials such as aluminium, it has some obvious winning points from the perspective of characteristics.

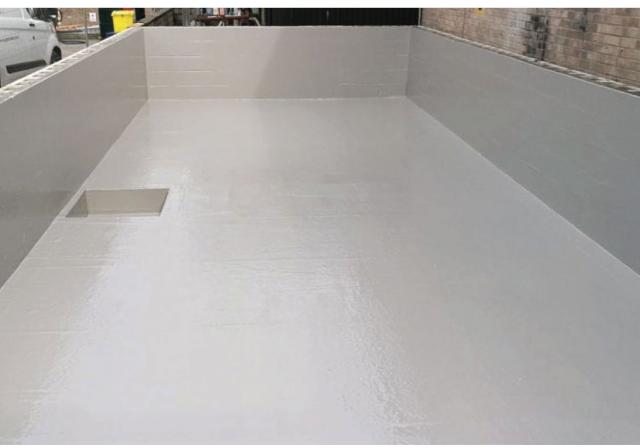

Technically speaking, it is awesome when you have installed it to places where receive of frequent impact, vibration and loads at a place that structural burden cannot be higher than original designed level. They are also good in resisting to wide varieties of chemicals, heat and foreign damages. Further inaction, once the perform is solidified, it can be located to the drawing tower during production that allows long strands to be pulled on the fibre. This complicated chain of processes are the key and essential one to make this end product's strength boosted with transparency effect. Fibreglass has a long shelf life, service period, waterproof and its greatest performances can be said to last it nearly 10 years without major maintenance required. It can be used for both indoor and outdoor where it exposes to sunlight's Ultraviolet (UV) ray without deterioration.

Technically speaking, it is awesome when you have installed it to places where receive of frequent impact, vibration and loads at a place that structural burden cannot be higher than original designed level. They are also good in resisting to wide varieties of chemicals, heat and foreign damages. Further inaction, once the perform is solidified, it can be located to the drawing tower during production that allows long strands to be pulled on the fibre. This complicated chain of processes are the key and essential one to make this end product's strength boosted with transparency effect. Fibreglass has a long shelf life, service period, waterproof and its greatest performances can be said to last it nearly 10 years without major maintenance required. It can be used for both indoor and outdoor where it exposes to sunlight's Ultraviolet (UV) ray without deterioration.

There are so many applications in glass-reinforced plastics material for the construction industry, such as storage tank, house building, roofing laminate, chimneys, window canopies, flooring, coping systems as an alternative to other metal usages. The industrial sector has also benefited with the working out of fibreglass materials since GRE pipe or GRP pipeline are widely accepted in both ground or underground systems. These are including drinking water, water treatment, wastewater plant, water distribution, desalination, liquefied petroleum, municipal waste, cold water system, heating or hot water lines, chemical plant, power plant, palm oil mill, firefighting and more. Furthermore, it is used extensively in oil and gas, rod pumping, reservoir and artificial lift systems. The lightweight feature with impressive strength is the one contributing the most fact when specifier chooses to use fibreglass.

There is a list of more within the installation of glass fibre by players in the fibreglass manufacturing line, including components across multiple sectors. Contractors and end-users have used from large commercial wind turbine blades, youth recurve, longbows, FRP vessel, FRP tank, chemical equipment, drum sets, ship hulls, pole vaulting poles, equipment handles (Hammers, axes, etc.), traffic lights, RF coils used in MRI scanners, surfboard, tent pole, helicopter rot blade, water-pipe, rowing shell, antenna cover, its related structures, sub-sea protection cover, water slides, fish pond, fibreglass lining, composite column, helmet, protective gear, sports floor, sport, equipment, asphalt pavement reinforcement, mesh interlayer, fabric mesh, orthopaedic casts, grating, oil rig, ship walkway, handrail and other feasible functional items.

There is a list of more within the installation of glass fibre by players in the fibreglass manufacturing line, including components across multiple sectors. Contractors and end-users have used from large commercial wind turbine blades, youth recurve, longbows, FRP vessel, FRP tank, chemical equipment, drum sets, ship hulls, pole vaulting poles, equipment handles (Hammers, axes, etc.), traffic lights, RF coils used in MRI scanners, surfboard, tent pole, helicopter rot blade, water-pipe, rowing shell, antenna cover, its related structures, sub-sea protection cover, water slides, fish pond, fibreglass lining, composite column, helmet, protective gear, sports floor, sport, equipment, asphalt pavement reinforcement, mesh interlayer, fabric mesh, orthopaedic casts, grating, oil rig, ship walkway, handrail and other feasible functional items.

FRP production is typically consisting of dual unique manufacturing steps that include how its raw material that is fibrous will be formed or produced at first; while the latter one will be how the matrix will be getting its bonding via a specialized process in the time of moulding. Fibre-reinforced plastic will be applicable to some range of design program that requires definite tolerance, light-weight standard, parts simplifying and precision engineering in operation and manufacturing. The moulded polymer product is good to be used because of its cost competitiveness when the project has a tight guideline to meet since it can also make cheaper raw materials while manufacturing process is much simpler, after quicker to be enjoyed. Comparing it to homogeneous products that are having similar characteristics, it is stronger and greater tolerance.

Material properties are something that will not be so obvious until they affect severely onto the structure such as from the load ratio as compared to other elements. For instance, some of the mechanical design of machinery and buildings have not incorporated any of the heavier loads imposed by the materials. The supporting cannot be withstood with such stress, therefore, affecting the safety reading and durability of overall. Fibreglass is able to cut the weight of such pressure up to sixty per cent as compared to traditional material, the aluminium. Technically and economically speaking, the overall production costs of the end product will be further reduced, making owners can allocate other financial capabilities to other aspects in the budget, with the proportionate value attributable to the specified need.

Material properties are something that will not be so obvious until they affect severely onto the structure such as from the load ratio as compared to other elements. For instance, some of the mechanical design of machinery and buildings have not incorporated any of the heavier loads imposed by the materials. The supporting cannot be withstood with such stress, therefore, affecting the safety reading and durability of overall. Fibreglass is able to cut the weight of such pressure up to sixty per cent as compared to traditional material, the aluminium. Technically and economically speaking, the overall production costs of the end product will be further reduced, making owners can allocate other financial capabilities to other aspects in the budget, with the proportionate value attributable to the specified need.

Fibreglass Product

Advantages of Fibreglass

Lightweight

Heat Resistant

Chemical Resistant

High Tensile

Durable

Low Cost

Contact us today for your Fibreglass Coating and Materials in Malaysia.