Material

Foam

Nov 2 2022

Polymer foam or generally refer as foam in construction term is a solid or liquid product that formed from a polymer material. The solidity of foam is dependent on the amount of air bubble or air tunnels in it when mixing the solid and gas phase of the polymer material. It is a very versatile material ranging from food containers to sound insulation material for room or building.

Introduction

The common polymer that made up this foam includes polystyrene (PS), polyurethane (PU), polyethylene (PE), polyvinyl chloride (PVC), polypropylene (PP), etc. This kind of material is so widely used because they are usually low in density, lightweight and can be made into a flexible or rigid product. Certain polymer materials also able to provide the extra feature of thermal resistant, sound insulation, shock absorption, moisture resistance, etc. Although polymer foam is very useful in many fields, it raises a concern in construction for it's usually not being environmentally friendly and not a green product.Applications

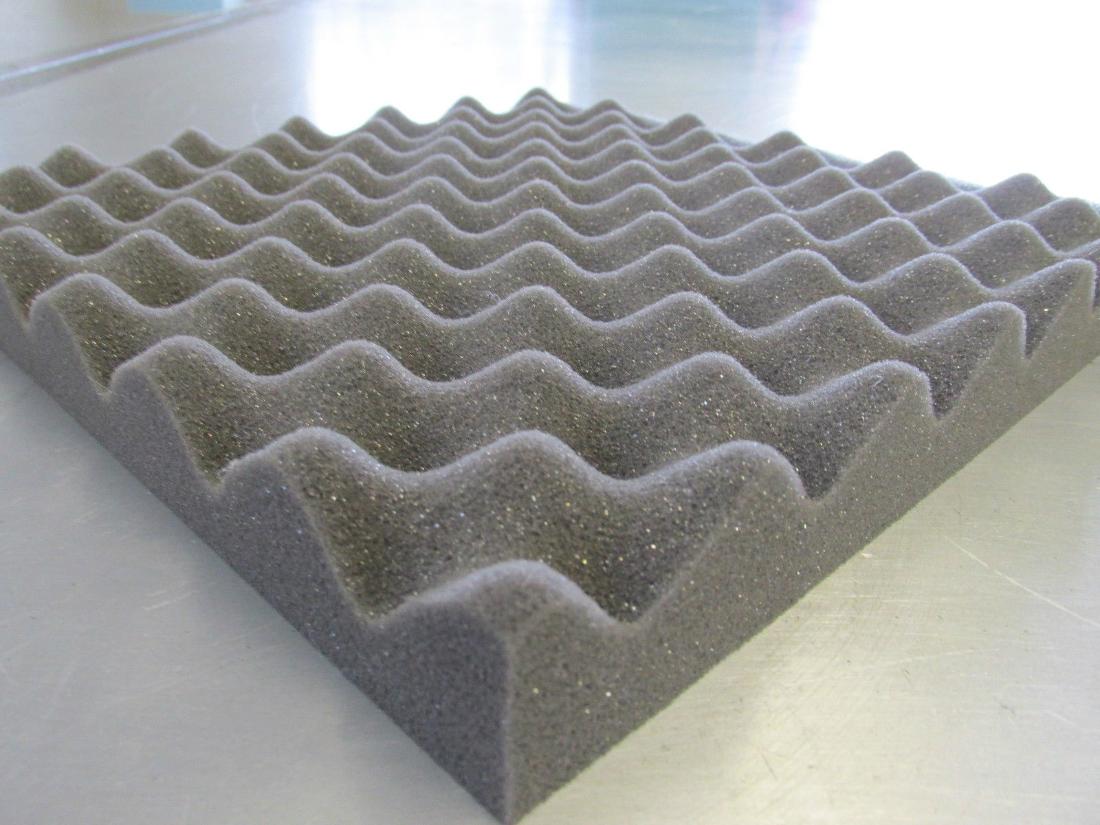

One of the most common forms is the soundproof foam or some also refer to acoustic foam. The foam is usually in egg box style like damping structure is design to increase the distance between source and receiver by acting as a noise barrier to damping the sound wave. Soundproofing foam does not entirely block the sound through a panel or wall but rather good at reducing the echoes in a room. Although there are still better soundproofing methods like sheetrock and brick materials, adding mass and renovate a complete room or house are not likely to be happening if you want a fast and economical solution. The foam can be made in several different thickness, sizes, and colors. It is commonly attached to wall, ceiling and also a door. Certain soundproofing foam also got the extra feature of fire retardants which slow down or stop the fire spread. Commonly Space or room that commonly using this foam is the gymnasium and also the music studio. Often foam is made up of polyethylene (PE) as this material are lightweight, durable and resilient. This PE foam sometimes also refer to as Expanded polyethylene (EPE) foam. The product can be pouches, board cuts, bundles or tubing package. It can usually be seen on packaging fragile or glossy product like the phone, glass, fruit, electrical hardware, laptop, etc because of it chemically resilient and shock absorbing. EPE foam and Expanded polypropylene (EPP) foam has many similarities. However, EPP has lower toxin or totally non-toxic because of its heat resistant and slower natural breakdown. Another famous foam is the memory foam which can also refer to polyurethane(PU) foam as the memory foam consist mainly of PU. To add more connection in its usage it was also named as memory foam pillow and memory foam mattress. This memory foam able to provide good support back, relieve paint and relaxing position. So material like this is usually good for the special need individual and suitable for a place like a hospital and home.

In construction, a foam can be used as an adhesive to mix with concrete which names as foam concrete or Cellular lightweight concrete (CLC). The production of foam concrete would reduce the usage of coarse aggregate or none at all as this materials would sink in the concrete and might cause segregation. Compare to normally prepared concrete, form concrete are lighter in weight and better workability but normal concrete are usually better at the load bearing application. Another similar product is the air entrained concrete which is also lightweight but with one of the difference is that air entrained takes in more air. Extra pozzolanas like fly ash or silica fume are usually added into the foam concrete to increase its versatility, durability, and also be more economical. Hardened foam concrete also performs well at a low-temperature environment because of its good resistance against thawing and freezing. The drawback of this foam concrete is usually longer in cement mixing time, long time for finishing and might take even longer if the environment is humid or mixture presence more water. The usual way to counter the drawback is usually using the precast foam concrete as it does not dependant on onsite weather or environment issue.

Contact us today for your foam supplier Malaysia.

In construction, a foam can be used as an adhesive to mix with concrete which names as foam concrete or Cellular lightweight concrete (CLC). The production of foam concrete would reduce the usage of coarse aggregate or none at all as this materials would sink in the concrete and might cause segregation. Compare to normally prepared concrete, form concrete are lighter in weight and better workability but normal concrete are usually better at the load bearing application. Another similar product is the air entrained concrete which is also lightweight but with one of the difference is that air entrained takes in more air. Extra pozzolanas like fly ash or silica fume are usually added into the foam concrete to increase its versatility, durability, and also be more economical. Hardened foam concrete also performs well at a low-temperature environment because of its good resistance against thawing and freezing. The drawback of this foam concrete is usually longer in cement mixing time, long time for finishing and might take even longer if the environment is humid or mixture presence more water. The usual way to counter the drawback is usually using the precast foam concrete as it does not dependant on onsite weather or environment issue.

Advantages

foam product usually has the following advantage:Lightweight

High Flexibility

Good Chemical resistance

Popular foam product

Precast foam concrete

Soundproof foam (acoustic foam)

Polyethylene foam (Expanded polyethylene foam,EPE)

Expanded Polypropylene foam (EPP)

Polyurethane (PU) foam

Memory foam

Foam Sealer

Contact us today for your foam supplier Malaysia.