Structure

Machine Platform

Sep 26 2020

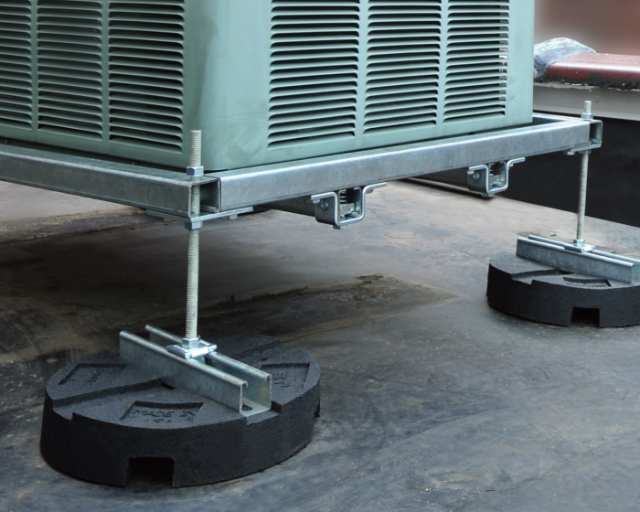

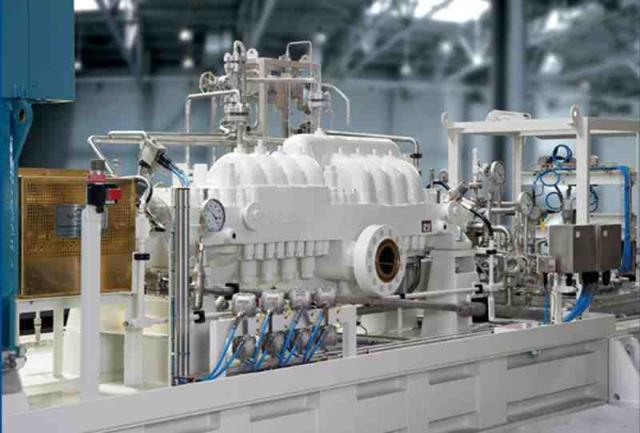

There is a wide range of machinery and equipment that needed a platform as well as the foundation for them to carry out their maximum potential, in different kinds of sectors. First of the reason is that the alignment when the technical team is examining the balancing of parts for that machine. Many workshops do the installation of a fabricated item as the attachment of certain pieces of equipment and usually, precision in levelling must be there to investigate if there are any weaknesses caused by improper design, installation as well as after-usage condition. Especially when working with the precision engineering field, any millimetre will cause a huge difference in completed work by the machine itself. The essential of getting accuracy for the end product to be there so safety and financial benefits would not be affected.

Working or not is also another issue when platform is not flat enough, some equipment might not be functioning well and certain machines could even not able to start for testing or commissioning. Furthermore, there are chances which the machine could just breakdown easily when it is operating in a highly un-flatten platform after a certain period of duration. There are also detector can be built within the piece of machine, making the smart device able to highlight when the levelling of the base is not appropriately there. In addition, a gauge used by service technician externally does always have such function, either manually adjusted by him or through laser pointer with the smart data collector. Most importantly to highlight here is that the platform is the preliminary for a successful end product assembly.

Working or not is also another issue when platform is not flat enough, some equipment might not be functioning well and certain machines could even not able to start for testing or commissioning. Furthermore, there are chances which the machine could just breakdown easily when it is operating in a highly un-flatten platform after a certain period of duration. There are also detector can be built within the piece of machine, making the smart device able to highlight when the levelling of the base is not appropriately there. In addition, a gauge used by service technician externally does always have such function, either manually adjusted by him or through laser pointer with the smart data collector. Most importantly to highlight here is that the platform is the preliminary for a successful end product assembly.

Specification of platform done by fabricator usually made up of steel or concrete, although there are possibilities to be manufactured using other materials such as aluminium or even wood. Because of steel and concrete are the best combination for structural as well as heavy-duty support. The concrete grade can go up to so many levels but of course, it can be adjusted based on the requirement since as higher as the properties, the price will also be followed with the hiking cost to end-user. Nevertheless, steel is also important whether adding into the concrete as the reinforcement bars to the foundation or another structural setup, or it can be standing independently underneath the slab or the machine to support both dead and live loads.

An engineer will do the calculation based on many factors and then advise the fabricator for getting the right materials to build a robust platform while keeping the cost low for end-user. There are several methods to improve the strengths of metal, including transformation hardening, cold working, precipitation hardening and solid-solution hardening. On the other hand, the concrete's strength of compressive can be elevated through a few of the ways, from the most common to complicated costly kind. First would be the admixture, then water-cement ratio, cement type and its numerical quantity, gradation and type of the aggregates since the machine might or might be as heavy as we think. Finally can use other materials from supplementary cementitious range.

An engineer will do the calculation based on many factors and then advise the fabricator for getting the right materials to build a robust platform while keeping the cost low for end-user. There are several methods to improve the strengths of metal, including transformation hardening, cold working, precipitation hardening and solid-solution hardening. On the other hand, the concrete's strength of compressive can be elevated through a few of the ways, from the most common to complicated costly kind. First would be the admixture, then water-cement ratio, cement type and its numerical quantity, gradation and type of the aggregates since the machine might or might be as heavy as we think. Finally can use other materials from supplementary cementitious range.

Machinery that will use the platform can be a lot but let us focus on industry-based for the discussion basis, for instance, a working platform that is elevated that common made by steel structure with column and beam that are huge underneath. One of the reasons why the platform might be jacked up to a certain height could due to the potential exposure to a specific level of water or other chemicals, in the processing plant such as water treatment plant. This is quite popular design within such plant as contractors will be required to excavator even deeper while the erection of equipment and pedestrian way on top of the chemical and water. This is also applicable to sewerage processing factory or sludge treatment mill within certain factories.

There are also temporary as well as permanent platforms built for various purposes, whereas the temporary one more towards for maintenance, overhaul, upkeeping or inspection usage. Many of the temporary platforms can either be portable, dismantlable, height-adjustable or expandable in term of dimension. Construction uses this kind of aerial working platform or gondola (some people park this equipment to this category too) for high rise or areas that might be dangerous (or unreachable) if not elevated. The supporting platform can also solve heavy machinery's fixed and fluctuating loads while in operation which cannot be withstood by the existing floor mainly made by conventional concrete which had not been strengthened yet.

There are also temporary as well as permanent platforms built for various purposes, whereas the temporary one more towards for maintenance, overhaul, upkeeping or inspection usage. Many of the temporary platforms can either be portable, dismantlable, height-adjustable or expandable in term of dimension. Construction uses this kind of aerial working platform or gondola (some people park this equipment to this category too) for high rise or areas that might be dangerous (or unreachable) if not elevated. The supporting platform can also solve heavy machinery's fixed and fluctuating loads while in operation which cannot be withstood by the existing floor mainly made by conventional concrete which had not been strengthened yet.

Material of Platform

Steel

Concrete

Aluminium

Wooden

Hybrid

Floating

Industry Usage

Water Treatment Plant

Palm Oil Mill

Production Floor

Refinery Plant

Machinery Workshop

Construction

Contact us today for your Machine Platform Materials and Fabricator in Malaysia.