Material

Bolt and Nut Supplier in Malaysia: The Unsung Heroes of Structural Integrity

Jul 11 2025

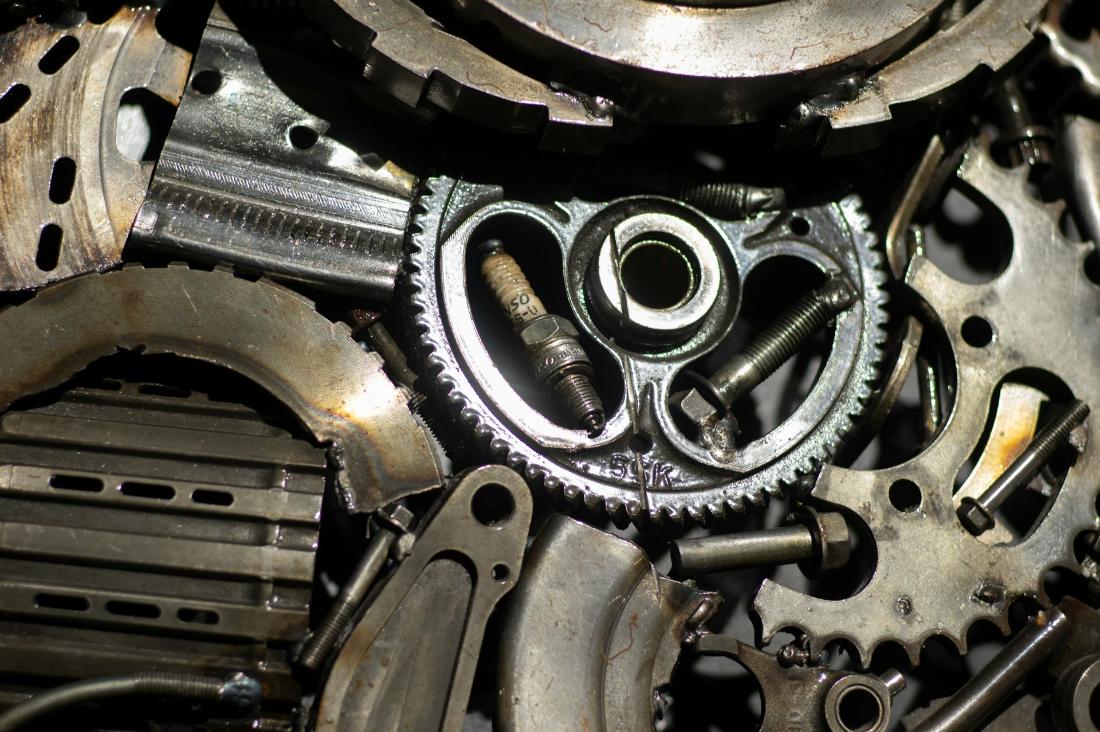

In the intricate world of construction, manufacturing, and industrial assembly, few components are as fundamentally important yet frequently overlooked as bolts and nuts. These small but mighty fasteners hold together everything from towering skyscrapers to delicate electronics, making the role of a bolt and nut supplier in Malaysia far more critical than most people realize. Behind every secure structure and reliable machine lies a carefully selected fastener that has been sourced, tested, and supplied by professionals who understand the immense responsibility that comes with their trade.

The Malaysian market presents unique challenges for fastener suppliers. The country's tropical climate, with its high humidity and salty coastal air, demands bolts and nuts with superior corrosion resistance. Industrial applications in oil refineries or offshore platforms require materials that can withstand extreme pressures and temperatures. Meanwhile, the construction boom across major cities needs fasteners that meet stringent safety standards while keeping pace with ambitious project timelines. A reputable supplier does more than just stock hardware—they serve as technical advisors, helping engineers and builders select the right fastening solutions for each specific application.

The Vital Role of Quality Fasteners in Malaysian Industries

Walk through any major construction site in Kuala Lumpur's bustling city center or Penang's industrial zones, and you'll witness thousands of bolts and nuts performing their silent but essential work. In building construction, structural bolts secure steel beams that form a skyscraper's skeleton, while anchor bolts embed themselves in concrete foundations, withstanding tremendous loads over decades of service. The difference between a fastener that lasts and one that fails often comes down to the supplier's expertise in material selection and quality assurance.

Manufacturing plants present another demanding environment for fasteners. Automotive assembly lines consume vast quantities of specially coated bolts that resist vibration loosening in vehicles. Electronics manufacturers need miniature fasteners with precise tolerances for sensitive equipment. Food processing facilities require stainless steel fasteners that won't contaminate products while withstanding frequent washdowns. Each sector has unique requirements that go far beyond the simple "nuts and bolts" stereotype.

The maintenance, repair, and operations (MRO) sector keeps Malaysian industries running smoothly by ensuring timely access to replacement fasteners. When a critical machine goes down because of a single failed bolt, the ability to quickly source an exact replacement becomes invaluable. Reliable suppliers maintain extensive inventories while providing technical support to help identify obscure or obsolete fasteners, minimizing costly downtime for their clients.

Navigating the Complex World of Fastener Specifications

What appears as a simple metal pin and threaded collar actually represents a highly engineered component with numerous critical specifications. The diameter and thread pitch must match perfectly—a difference of even a fraction of a millimeter can lead to joint failure. Material composition determines strength and corrosion resistance, with options ranging from standard carbon steel to exotic alloys like Inconel for extreme environments.

Surface treatments add another layer of complexity. Zinc plating provides basic corrosion protection for indoor applications, while hot-dip galvanizing offers superior defense against Malaysia's humid climate. More specialized coatings like Dacromet or Geomet resist salt spray in coastal areas, and Xylan coatings reduce friction in moving assemblies. A knowledgeable supplier guides customers through these options, preventing costly mismatches between fastener capabilities and application demands.

International standards govern fastener quality, with ISO, ASTM, and DIN being the most widely recognized. In Malaysia, Sirim certification provides additional assurance of compliance with local regulations. Reputable suppliers maintain detailed certification records for their products, allowing engineers to verify that fasteners meet project specifications before installation.

The Malaysian market presents unique challenges for fastener suppliers. The country's tropical climate, with its high humidity and salty coastal air, demands bolts and nuts with superior corrosion resistance. Industrial applications in oil refineries or offshore platforms require materials that can withstand extreme pressures and temperatures. Meanwhile, the construction boom across major cities needs fasteners that meet stringent safety standards while keeping pace with ambitious project timelines. A reputable supplier does more than just stock hardware—they serve as technical advisors, helping engineers and builders select the right fastening solutions for each specific application.

The Vital Role of Quality Fasteners in Malaysian Industries

Walk through any major construction site in Kuala Lumpur's bustling city center or Penang's industrial zones, and you'll witness thousands of bolts and nuts performing their silent but essential work. In building construction, structural bolts secure steel beams that form a skyscraper's skeleton, while anchor bolts embed themselves in concrete foundations, withstanding tremendous loads over decades of service. The difference between a fastener that lasts and one that fails often comes down to the supplier's expertise in material selection and quality assurance.

Manufacturing plants present another demanding environment for fasteners. Automotive assembly lines consume vast quantities of specially coated bolts that resist vibration loosening in vehicles. Electronics manufacturers need miniature fasteners with precise tolerances for sensitive equipment. Food processing facilities require stainless steel fasteners that won't contaminate products while withstanding frequent washdowns. Each sector has unique requirements that go far beyond the simple "nuts and bolts" stereotype.

The maintenance, repair, and operations (MRO) sector keeps Malaysian industries running smoothly by ensuring timely access to replacement fasteners. When a critical machine goes down because of a single failed bolt, the ability to quickly source an exact replacement becomes invaluable. Reliable suppliers maintain extensive inventories while providing technical support to help identify obscure or obsolete fasteners, minimizing costly downtime for their clients.

Navigating the Complex World of Fastener Specifications

What appears as a simple metal pin and threaded collar actually represents a highly engineered component with numerous critical specifications. The diameter and thread pitch must match perfectly—a difference of even a fraction of a millimeter can lead to joint failure. Material composition determines strength and corrosion resistance, with options ranging from standard carbon steel to exotic alloys like Inconel for extreme environments.

Surface treatments add another layer of complexity. Zinc plating provides basic corrosion protection for indoor applications, while hot-dip galvanizing offers superior defense against Malaysia's humid climate. More specialized coatings like Dacromet or Geomet resist salt spray in coastal areas, and Xylan coatings reduce friction in moving assemblies. A knowledgeable supplier guides customers through these options, preventing costly mismatches between fastener capabilities and application demands.

International standards govern fastener quality, with ISO, ASTM, and DIN being the most widely recognized. In Malaysia, Sirim certification provides additional assurance of compliance with local regulations. Reputable suppliers maintain detailed certification records for their products, allowing engineers to verify that fasteners meet project specifications before installation.

Specialized Fastener Solutions for Malaysian Challenges

The country's development boom has created demand for specialized fasteners that address unique local conditions. Construction projects in soft soil areas require extra-long anchor bolts that penetrate to stable ground. Coastal developments need marine-grade fasteners that resist saltwater corrosion. High-rise buildings in seismic zones demand structural bolts with precisely calibrated ductility to flex during earthquakes without breaking.

Industrial applications present their own specialized requirements. Oil and gas installations use high-strength bolts that maintain tension under extreme temperatures and pressures. Renewable energy projects, particularly solar farms, need UV-resistant fasteners that won't degrade under constant sun exposure. Railway infrastructure requires vibration-resistant fasteners that stay secure despite constant movement.

Even traditional sectors like agriculture have unique fastener needs. Rubber plantation equipment uses special self-locking nuts that won't loosen from tractor vibrations. Palm oil processing machinery requires easy-to-clean fastener designs that prevent product buildup in hygienic areas. A supplier with deep market understanding stocks these specialized items while maintaining the expertise to recommend optimal solutions.

The Supplier's Role in Quality Assurance and Traceability

In critical applications, a single faulty fastener can lead to catastrophic failures. The 2015 collapse of a pedestrian bridge in Kuala Lumpur served as a sobering reminder of how fastener quality impacts structural integrity. Responsible suppliers implement rigorous quality control measures, including batch testing for tensile strength, hardness, and dimensional accuracy. Many maintain in-house laboratories to verify material composition and coating thickness.

Traceability has become increasingly important, particularly for structural and safety-critical fasteners. Advanced suppliers use laser marking to imprint each bolt with unique identifiers that track it back to the production batch, heat treatment cycle, and quality test results. This level of documentation gives engineers confidence in the components holding their structures together.

Counterfeit fasteners pose a significant risk in the Malaysian market, with substandard products sometimes making their way into critical applications. Reputable suppliers combat this by maintaining direct relationships with certified manufacturers and refusing to deal in suspiciously low-priced goods of uncertain origin. Their technical staff can often spot counterfeit fasteners through subtle differences in marking, finish, or dimensional tolerances.

Inventory Management and Supply Chain Solutions

For contractors facing tight project schedules, fastener availability often determines whether work proceeds smoothly or grinds to a halt. Leading suppliers maintain extensive local inventories while utilizing sophisticated inventory management systems to prevent stockouts. Many offer vendor-managed inventory programs where they monitor customers' fastener usage and automatically replenish stocks before shortages occur.

Just-in-time delivery has become another valuable service, with suppliers coordinating deliveries to match construction timelines. Some provide pre-packaged fastener kits for specific assembly tasks, saving contractors time on sorting and counting components. For large projects, suppliers may establish on-site stores staffed by their personnel, ensuring instant access to required fasteners while maintaining accurate usage records.

Digital transformation has revolutionized fastener procurement. Many suppliers now offer online catalogs with detailed technical specifications, 3D models for engineering integration, and real-time inventory visibility. Mobile apps allow site supervisors to reorder fasteners instantly by scanning barcodes on empty bins, streamlining the replenishment process.

The country's development boom has created demand for specialized fasteners that address unique local conditions. Construction projects in soft soil areas require extra-long anchor bolts that penetrate to stable ground. Coastal developments need marine-grade fasteners that resist saltwater corrosion. High-rise buildings in seismic zones demand structural bolts with precisely calibrated ductility to flex during earthquakes without breaking.

Industrial applications present their own specialized requirements. Oil and gas installations use high-strength bolts that maintain tension under extreme temperatures and pressures. Renewable energy projects, particularly solar farms, need UV-resistant fasteners that won't degrade under constant sun exposure. Railway infrastructure requires vibration-resistant fasteners that stay secure despite constant movement.

Even traditional sectors like agriculture have unique fastener needs. Rubber plantation equipment uses special self-locking nuts that won't loosen from tractor vibrations. Palm oil processing machinery requires easy-to-clean fastener designs that prevent product buildup in hygienic areas. A supplier with deep market understanding stocks these specialized items while maintaining the expertise to recommend optimal solutions.

The Supplier's Role in Quality Assurance and Traceability

In critical applications, a single faulty fastener can lead to catastrophic failures. The 2015 collapse of a pedestrian bridge in Kuala Lumpur served as a sobering reminder of how fastener quality impacts structural integrity. Responsible suppliers implement rigorous quality control measures, including batch testing for tensile strength, hardness, and dimensional accuracy. Many maintain in-house laboratories to verify material composition and coating thickness.

Traceability has become increasingly important, particularly for structural and safety-critical fasteners. Advanced suppliers use laser marking to imprint each bolt with unique identifiers that track it back to the production batch, heat treatment cycle, and quality test results. This level of documentation gives engineers confidence in the components holding their structures together.

Counterfeit fasteners pose a significant risk in the Malaysian market, with substandard products sometimes making their way into critical applications. Reputable suppliers combat this by maintaining direct relationships with certified manufacturers and refusing to deal in suspiciously low-priced goods of uncertain origin. Their technical staff can often spot counterfeit fasteners through subtle differences in marking, finish, or dimensional tolerances.

Inventory Management and Supply Chain Solutions

For contractors facing tight project schedules, fastener availability often determines whether work proceeds smoothly or grinds to a halt. Leading suppliers maintain extensive local inventories while utilizing sophisticated inventory management systems to prevent stockouts. Many offer vendor-managed inventory programs where they monitor customers' fastener usage and automatically replenish stocks before shortages occur.

Just-in-time delivery has become another valuable service, with suppliers coordinating deliveries to match construction timelines. Some provide pre-packaged fastener kits for specific assembly tasks, saving contractors time on sorting and counting components. For large projects, suppliers may establish on-site stores staffed by their personnel, ensuring instant access to required fasteners while maintaining accurate usage records.

Digital transformation has revolutionized fastener procurement. Many suppliers now offer online catalogs with detailed technical specifications, 3D models for engineering integration, and real-time inventory visibility. Mobile apps allow site supervisors to reorder fasteners instantly by scanning barcodes on empty bins, streamlining the replenishment process.

Value-Added Services That Differentiate Suppliers

Beyond simply providing hardware, top-tier fastener suppliers offer services that solve broader customer challenges. Technical consulting helps engineers select optimal fasteners for new designs, considering factors like load requirements, environmental conditions, and installation methods. Many suppliers provide on-site training for construction crews on proper fastener handling, tightening techniques, and corrosion prevention.

Special processing saves customers time and labor. Suppliers may pre-cut threaded rod to specified lengths, assemble bolt-nut-washer kits, or apply thread-locking compounds at their facilities. Some offer custom packaging that organizes fasteners for specific assembly sequences, improving efficiency on production lines.

For challenging installations, suppliers can provide specialized tools like calibrated torque wrenches or hydraulic tensioning equipment. They often maintain libraries of international standards and technical references, helping customers navigate complex specification requirements.

Choosing the Right Fastener Supplier

With so much riding on fastener quality, selection of a supplier requires careful consideration. Technical capability should match project requirements—a supplier specializing in construction fasteners may lack the precision inventory needed for electronics manufacturing, while an industrial supplier might not stock the aesthetic fasteners required for architectural applications.

Quality certifications provide important indicators of reliability. Look for suppliers with ISO 9001 quality management systems and specific product certifications relevant to your industry. Membership in professional organizations like the Malaysian Structural Steel Association suggests commitment to industry best practices.

Financial stability matters more than many buyers realize. The fastener industry has seen numerous failures of undercapitalized importers who couldn't maintain quality consistency. Established suppliers with long track records and strong manufacturer relationships offer more reliable supply chains.

Customer service distinguishes exceptional suppliers. The ability to provide technical support after hours, accommodate emergency orders, and proactively suggest better fastener solutions demonstrates commitment to partnership rather than just transactional sales.

The Future of Fastening Technology in Malaysia

As Malaysian industries advance, fastener technology evolves to meet new challenges. Smart fasteners with embedded sensors can monitor tension loss or corrosion levels in critical connections. Self-locking designs using shape-memory alloys promise more reliable vibration resistance. Environmentally friendly coatings are replacing traditional treatments that contain hazardous substances.

Digital integration continues transforming the supply chain. Blockchain technology may soon provide immutable records of fastener provenance and quality testing. Augmented reality apps could help workers identify correct fasteners by simply pointing their phone at a bin. Predictive analytics will enable suppliers to anticipate customer needs before orders are placed.

Sustainability concerns are driving innovation in fastener recycling and remanufacturing. Some suppliers now offer take-back programs for used fasteners from demolition projects, properly sorting and processing them for reuse where possible. Lightweighting initiatives see engineers and suppliers collaborating to develop high-strength fasteners that use less material without compromising performance.

Conclusion: Small Components, Big Responsibilities

In a nation building its future through ambitious infrastructure projects and advanced manufacturing, the humble bolt and nut play an outsized role in ensuring safety, reliability, and progress. The best fastener suppliers understand that they're not just selling metal parts—they're providing the literal connections that hold Malaysia's development together.

From the PETRONAS Towers to the smallest electronics factory, quality fasteners make possible the structures and machines that define modern life. By choosing suppliers who combine technical expertise with rigorous quality standards and exceptional service, Malaysian industries can build with confidence, knowing their connections will hold firm against whatever challenges the tropical climate and demanding applications may bring.

The next time you cross a bridge, ride an elevator, or use a manufactured product, take a moment to appreciate the countless bolts and nuts performing their silent duty—and the knowledgeable suppliers who ensure these small but vital components are always there when needed, exactly as specified, and ready to withstand the test of time.

Beyond simply providing hardware, top-tier fastener suppliers offer services that solve broader customer challenges. Technical consulting helps engineers select optimal fasteners for new designs, considering factors like load requirements, environmental conditions, and installation methods. Many suppliers provide on-site training for construction crews on proper fastener handling, tightening techniques, and corrosion prevention.

Special processing saves customers time and labor. Suppliers may pre-cut threaded rod to specified lengths, assemble bolt-nut-washer kits, or apply thread-locking compounds at their facilities. Some offer custom packaging that organizes fasteners for specific assembly sequences, improving efficiency on production lines.

For challenging installations, suppliers can provide specialized tools like calibrated torque wrenches or hydraulic tensioning equipment. They often maintain libraries of international standards and technical references, helping customers navigate complex specification requirements.

Choosing the Right Fastener Supplier

With so much riding on fastener quality, selection of a supplier requires careful consideration. Technical capability should match project requirements—a supplier specializing in construction fasteners may lack the precision inventory needed for electronics manufacturing, while an industrial supplier might not stock the aesthetic fasteners required for architectural applications.

Quality certifications provide important indicators of reliability. Look for suppliers with ISO 9001 quality management systems and specific product certifications relevant to your industry. Membership in professional organizations like the Malaysian Structural Steel Association suggests commitment to industry best practices.

Financial stability matters more than many buyers realize. The fastener industry has seen numerous failures of undercapitalized importers who couldn't maintain quality consistency. Established suppliers with long track records and strong manufacturer relationships offer more reliable supply chains.

Customer service distinguishes exceptional suppliers. The ability to provide technical support after hours, accommodate emergency orders, and proactively suggest better fastener solutions demonstrates commitment to partnership rather than just transactional sales.

The Future of Fastening Technology in Malaysia

As Malaysian industries advance, fastener technology evolves to meet new challenges. Smart fasteners with embedded sensors can monitor tension loss or corrosion levels in critical connections. Self-locking designs using shape-memory alloys promise more reliable vibration resistance. Environmentally friendly coatings are replacing traditional treatments that contain hazardous substances.

Digital integration continues transforming the supply chain. Blockchain technology may soon provide immutable records of fastener provenance and quality testing. Augmented reality apps could help workers identify correct fasteners by simply pointing their phone at a bin. Predictive analytics will enable suppliers to anticipate customer needs before orders are placed.

Sustainability concerns are driving innovation in fastener recycling and remanufacturing. Some suppliers now offer take-back programs for used fasteners from demolition projects, properly sorting and processing them for reuse where possible. Lightweighting initiatives see engineers and suppliers collaborating to develop high-strength fasteners that use less material without compromising performance.

Conclusion: Small Components, Big Responsibilities

In a nation building its future through ambitious infrastructure projects and advanced manufacturing, the humble bolt and nut play an outsized role in ensuring safety, reliability, and progress. The best fastener suppliers understand that they're not just selling metal parts—they're providing the literal connections that hold Malaysia's development together.

From the PETRONAS Towers to the smallest electronics factory, quality fasteners make possible the structures and machines that define modern life. By choosing suppliers who combine technical expertise with rigorous quality standards and exceptional service, Malaysian industries can build with confidence, knowing their connections will hold firm against whatever challenges the tropical climate and demanding applications may bring.

The next time you cross a bridge, ride an elevator, or use a manufactured product, take a moment to appreciate the countless bolts and nuts performing their silent duty—and the knowledgeable suppliers who ensure these small but vital components are always there when needed, exactly as specified, and ready to withstand the test of time.