Material

Aluminium Composite Panel (ACP)

Aug 17 2020

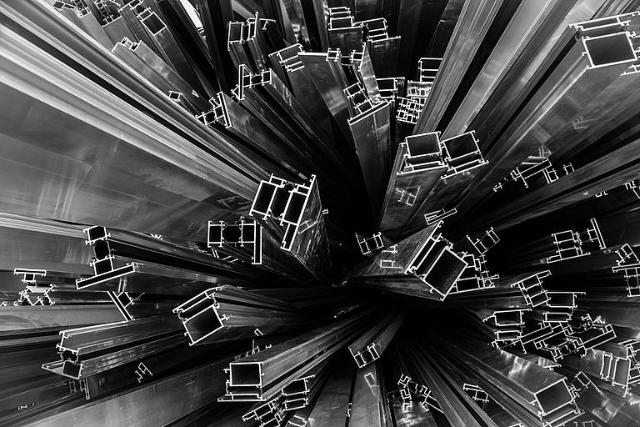

ACP is also known fully as an aluminium composite panel, where it is produced by two sheets of thin aluminium to a core of polymer. It was formed originally from rolling form of aluminium material, it comprises of few layers that will be bonded as a whole in order to have multiple layers, that sandwich structure is cored laminate. In addition to the facade, it can be used in the industrial sector as a structural panel. Anyhow, it can be manufactured and be addressed as a composite panel even though by other elements. There are several raw materials in the gameplay for the composite panels, such as ceramic, metal, glass, wood, plastic or any other range of fibre-based composite materials. Many claims that two major panel of composite applicable for a wall as well as a roof, divided into single or twin panels.

A composite panel is getting more and more common in the building sector as technology advances since the outlook steel or timber-alike kind of range is still eye-catching when you walk across the street. But instead of using the real steel, the wood of solid, the support structurally and strength values are equal when installing it to similar places. Various classical one available in the market is inclusive of fibreglass, aluminium and wooden oriented. All of these units offer the same materials with several layers, but in between slotted in with core lighter in weight materials, forming a sandwich and therefore also called a sandwich panel. The outer and core are acting as protective, highly correlated in term of strength. For instance, polyethylene is the one acting as the core.

A composite panel is getting more and more common in the building sector as technology advances since the outlook steel or timber-alike kind of range is still eye-catching when you walk across the street. But instead of using the real steel, the wood of solid, the support structurally and strength values are equal when installing it to similar places. Various classical one available in the market is inclusive of fibreglass, aluminium and wooden oriented. All of these units offer the same materials with several layers, but in between slotted in with core lighter in weight materials, forming a sandwich and therefore also called a sandwich panel. The outer and core are acting as protective, highly correlated in term of strength. For instance, polyethylene is the one acting as the core.

Aluminium works the best if you require something that is so durable because it can last longer than expected, comparing it to wood and steel (mild steel). The reason is pretty simple as aluminium is a non-corrosive material, unlike steel that needs coating or only stainless steel can do such function. When it is being installed to outdoor as a decorative facade, panel or awning, its weather-withstandability makes it so robust that no acid rain or ultraviolet (UV) from sunlight can damage it. Furthermore, when taking it to be side-by-side by timber made panel, its termite-resistant makes more sense for cost-saving while the texture of aluminium with timber colour possibly making it one of the best substitute too. At the meantime, its wear and tear are not so much so no frequent up keeping works to be done which incur costs such as renting gondola or skylift for a taller building.

More to the point, aluminium is lighter in weight, saving tons of cost when the structural burden is to be reduced by the owner for the tightness of budget. Aluminium's variety in term of shape, colour and pattern are also as wide range as per other materials in which making designers love this product more than other materials. The lightweight and versatility features are so essential when the project is anything about high-rise skyscraper, any slight benefit will be magnified dramatically. Aluminium is also having compatible strength-to-weight ratio with relatively low in acquisition cost, among other composite panel or outdoor usage. Its material is also environmental-friendly that allows recyclability, scrap will never be a waste for this product. Last but not least, you can enjoy saving in electricity bill since the gaining of thermal stability for energy efficiency will be there for you.

More to the point, aluminium is lighter in weight, saving tons of cost when the structural burden is to be reduced by the owner for the tightness of budget. Aluminium's variety in term of shape, colour and pattern are also as wide range as per other materials in which making designers love this product more than other materials. The lightweight and versatility features are so essential when the project is anything about high-rise skyscraper, any slight benefit will be magnified dramatically. Aluminium is also having compatible strength-to-weight ratio with relatively low in acquisition cost, among other composite panel or outdoor usage. Its material is also environmental-friendly that allows recyclability, scrap will never be a waste for this product. Last but not least, you can enjoy saving in electricity bill since the gaining of thermal stability for energy efficiency will be there for you.

Aluminium application can be as varied as your imagination, therefore, it is vital for designer to discuss accordingly side-by-side with owner of the project. Specification stage is a phase that most of the stakeholders in a project discuss about the pros and cons using each of every materials, to achieve certain mutual agreed objective. For instance, if cost is never a concern for a luxury high-end bungalow, aluminium composite panel is also having the utmost advantages of applying it since its provision of quality can be optimized through proper adjustment in term of aesthetic, colour boldness, special moulded pattern to tolerance of material wastages due to the uniqueness in elegance style. Some very fine-crafted wooden products or other handmade stone by professionals can be as expensive as expected, but aluminium composite products will still be having winning position against all of the others.

More or less, ACP is mostly used for awning, decorative facade, shelter, roofing, interior, exterior, walkway, cladding, insulation, signage and some others. Its area can be bus stop, school, community hall, car porch, high rise, condominium, landed semi-detached house, office, shop lot, showroom, exhibition hall, hotel, government authorities, shopping mall, army camp, pedestrian street, road side, restaurant and further ranges that could not be mentioned all here. The point is that, aluminium composite sheet like this can make awesome additional selling point to uplift your properties and project values with minimal cost of investment. Many contractors found it easy to install too,

More or less, ACP is mostly used for awning, decorative facade, shelter, roofing, interior, exterior, walkway, cladding, insulation, signage and some others. Its area can be bus stop, school, community hall, car porch, high rise, condominium, landed semi-detached house, office, shop lot, showroom, exhibition hall, hotel, government authorities, shopping mall, army camp, pedestrian street, road side, restaurant and further ranges that could not be mentioned all here. The point is that, aluminium composite sheet like this can make awesome additional selling point to uplift your properties and project values with minimal cost of investment. Many contractors found it easy to install too,

ACP Product

Advantages of Aluminium

Lightweight

Stain Resistant

Chemical Resistant

High Strength

Durable

Low Cost

Contact us today for your ACP Materials and Contractor in Malaysia.