Structure

Grille

Aug 12 2021

Since grille has a wide range of applications, we should introduce one by one generally on its main usage from various sectors. Grille is defined as a wall opening side-by-side or attaching as another barrier while it can be also installed in a metal sheet. Its opening has several slits and a bigger size sometimes can be over hundreds in term of measure. The key function usually is allowing fresh air ventilate from the one-to-another side while providing an unobstructed view from one side (or some are having both sides). At the same time, it can also be done to the water element, preventing it from splashing in such as rainwater. It can be made by aluminium, bronze, iron, wood to many others. Furthermore, it will have also one benefit purposely for those who want to permit sunlight to go through partially while providing privacy to protect the users.

On the other hand, a grill is also a good idea but there is a difference with grille as it is the grated metal cooking utensil or it can also be known as direct heat cook over. Grille is, strictly speaking, a network of bars made up of several raw materials as a screen or a blocking panel. It also enables the certain size of objects can come in or go out from the room, building, the other side of the wall too by building it, provided the design is appropriately putting on for such purpose. Nevertheless, HVAC grille is famous too as this vent cover (or ventilation cover is its alternate name) as well as the grille cover for engineering industry such as automotive manufacturing. Most of the vehicles will have protection shield at the front end of engine and radiator installed to the vehicle for air to exit or enter; it can be categorized under heating, cooling, air-conditioning (HVAC) too.

On the other hand, a grill is also a good idea but there is a difference with grille as it is the grated metal cooking utensil or it can also be known as direct heat cook over. Grille is, strictly speaking, a network of bars made up of several raw materials as a screen or a blocking panel. It also enables the certain size of objects can come in or go out from the room, building, the other side of the wall too by building it, provided the design is appropriately putting on for such purpose. Nevertheless, HVAC grille is famous too as this vent cover (or ventilation cover is its alternate name) as well as the grille cover for engineering industry such as automotive manufacturing. Most of the vehicles will have protection shield at the front end of engine and radiator installed to the vehicle for air to exit or enter; it can be categorized under heating, cooling, air-conditioning (HVAC) too.

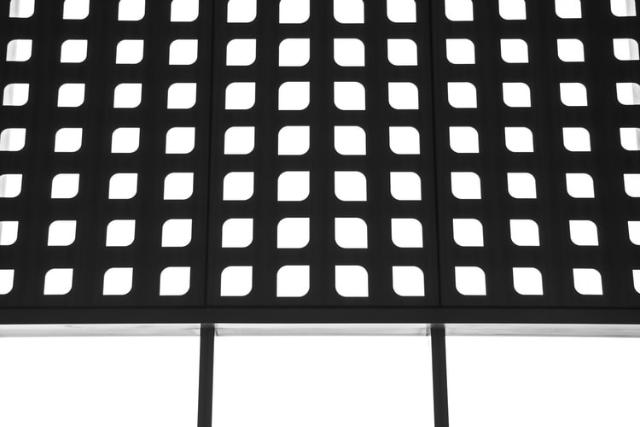

There is a range of materials can be fabricated to grille, from bronze, concrete jail, mild steel, cast iron and wrought iron, stainless steel, aluminium, aluminium, wood and other natural or synthetic raw elements. Workability of some of them will be explained as per the following, starting with bronze as it is copper as a base that is fallen under the alloy, while harder than pure copper after added in other elements such as tin (another metal that can aid in the formation of toughness). Bronze can have higher conductivity against electricity, heat and resist better towards corrosion as well as most other steels and metal fatigue. In the perspective of science, the meaning of fatigue is actually material weakening due to the loading cyclically resulted from localized as well as progressive damage of structural, also welcoming the unwanted cracks.

Famous one for window grilles fabrication would be the wrought iron, cast iron, steel and aluminium. Aluminium is undoubtedly the lightweight alternative to steel because its strength-to-weight ratio is optimized because of its natural properties. Aluminium is cheaper than most of the metal while enjoying the features of them too. Further to the point, wrought iron is also having lesser carbon than cast iron, ductile and softening are then better too. It is also less fatigue symptom like most metal while deforming will occur before huge failing when it receives tremendous pressure externally. Comparing to stainless steel (SS), mild steel can be as useful as it with a lesser amount of investment required for that material, while it is good in weldability, recyclability, carbonized and many more. At the end of the story, depending on your design, budget and what other features you are looking at.

Famous one for window grilles fabrication would be the wrought iron, cast iron, steel and aluminium. Aluminium is undoubtedly the lightweight alternative to steel because its strength-to-weight ratio is optimized because of its natural properties. Aluminium is cheaper than most of the metal while enjoying the features of them too. Further to the point, wrought iron is also having lesser carbon than cast iron, ductile and softening are then better too. It is also less fatigue symptom like most metal while deforming will occur before huge failing when it receives tremendous pressure externally. Comparing to stainless steel (SS), mild steel can be as useful as it with a lesser amount of investment required for that material, while it is good in weldability, recyclability, carbonized and many more. At the end of the story, depending on your design, budget and what other features you are looking at.

Grille work is not an easy work though, many contractor and fabricator tend to use some easy-going materials such as aluminium and other metals. Although steel-based products tend to be more expensive, their sustainability in prolongation in useful life makes it an irreplaceable advantage for most people. However, there are also people who would like to use other than metal one, which is wooden grille, it can be also be coated with waterproof, termite-resistant, UV-resistant and even framed with automatic system as well as retractable. Many louvre, fence, gate, facade, ceiling, floor, roof or other building components use timber to fabricate for the sake of aesthetical effects.

Furthermore, grille is also possibly manufactured by ready-made series from the factory, the pros and cons are pretty simple such as cheaper in cost but limited design. It could be having more selections if your materials are needed by the market demand or trendy enough to produce more varieties. In addition, customized one seems losing their market share due to the setbacks from economies of scale production as well as not many consumers know where to get them (some do not even know there are customizable products). Metal fabricator, welding contractor, steel stockist, renovation specialist, designer, hardware dealer and trading houses will know where to obtain.

Furthermore, grille is also possibly manufactured by ready-made series from the factory, the pros and cons are pretty simple such as cheaper in cost but limited design. It could be having more selections if your materials are needed by the market demand or trendy enough to produce more varieties. In addition, customized one seems losing their market share due to the setbacks from economies of scale production as well as not many consumers know where to get them (some do not even know there are customizable products). Metal fabricator, welding contractor, steel stockist, renovation specialist, designer, hardware dealer and trading houses will know where to obtain.

Grille Application

Landed House

Condominium Balcony

Outdoor Event

Dining Area and Cafe

Industrial Plant and Factory

Commercial and Entertainment Venue

Materials of Grille

Aluminium Composite Panel (ACP)

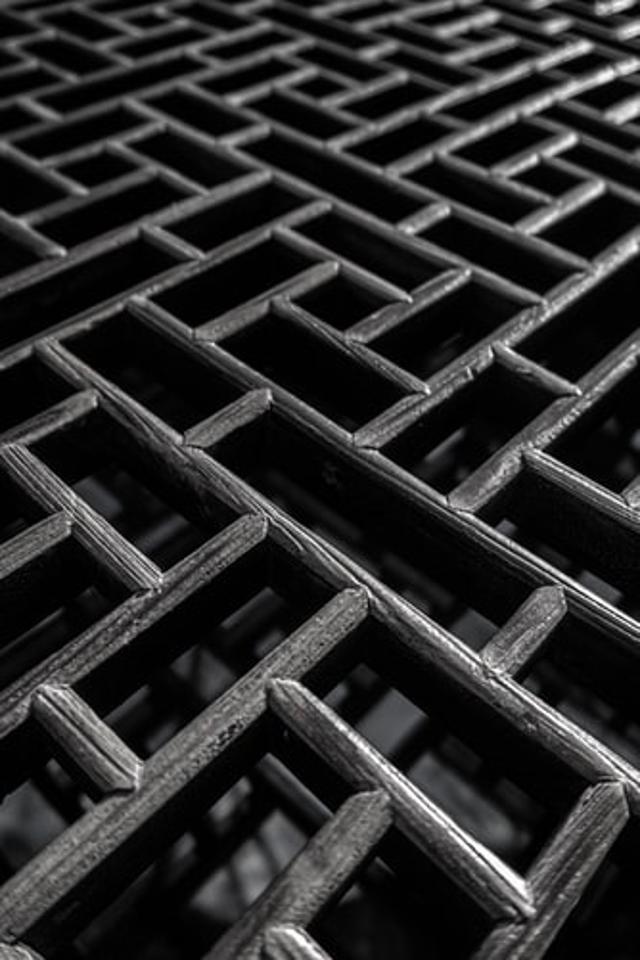

Wire Mesh and Reinforced Bar

Acrylic and Polycarbonate

Wooden and Composite

Vinyl and Plastic

Steel and Other Metals

Contact us today for your Grille Materials Supplier and Contractor in Malaysia.